Dump Trucks

Dump trucks are usually used in quarries to carry payload and have Diesel-Mechanical propulsion. Their payload capacity vary from 35 t to 70 t.

Medha’s electric powertrain and energy storage system kit caters to the full spectrum of sizes and capacity of the Dump trucks. Medha’s innovative electric powertrain offers a sustainable and efficient solution for road and offroad operations such as mining. The system features a high-torque Permanent Magnet Synchronous Motor (PMSM) coupled with a 6-speed heavy-duty gearbox for optimal performance across various terrain. An advanced motor controller ensures seamless power transfer between the battery and the motor, while the Vehicle Control Unit (VCU) optimizes system efficiency.

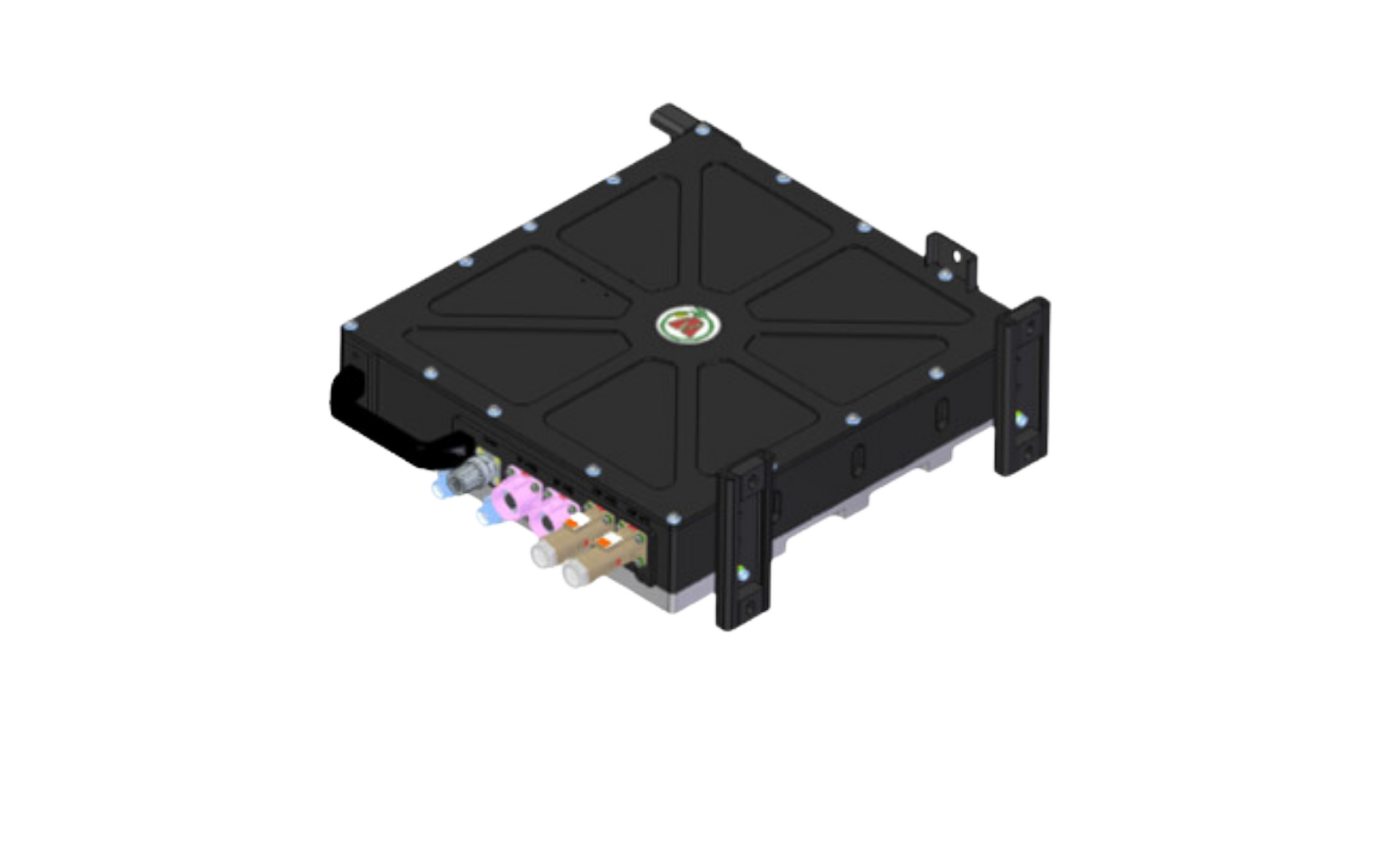

Integrated Electric Powertrain: Medha offers a complete powertrain solution, including the battery pack, designed for medium and heavy commercial vehicles

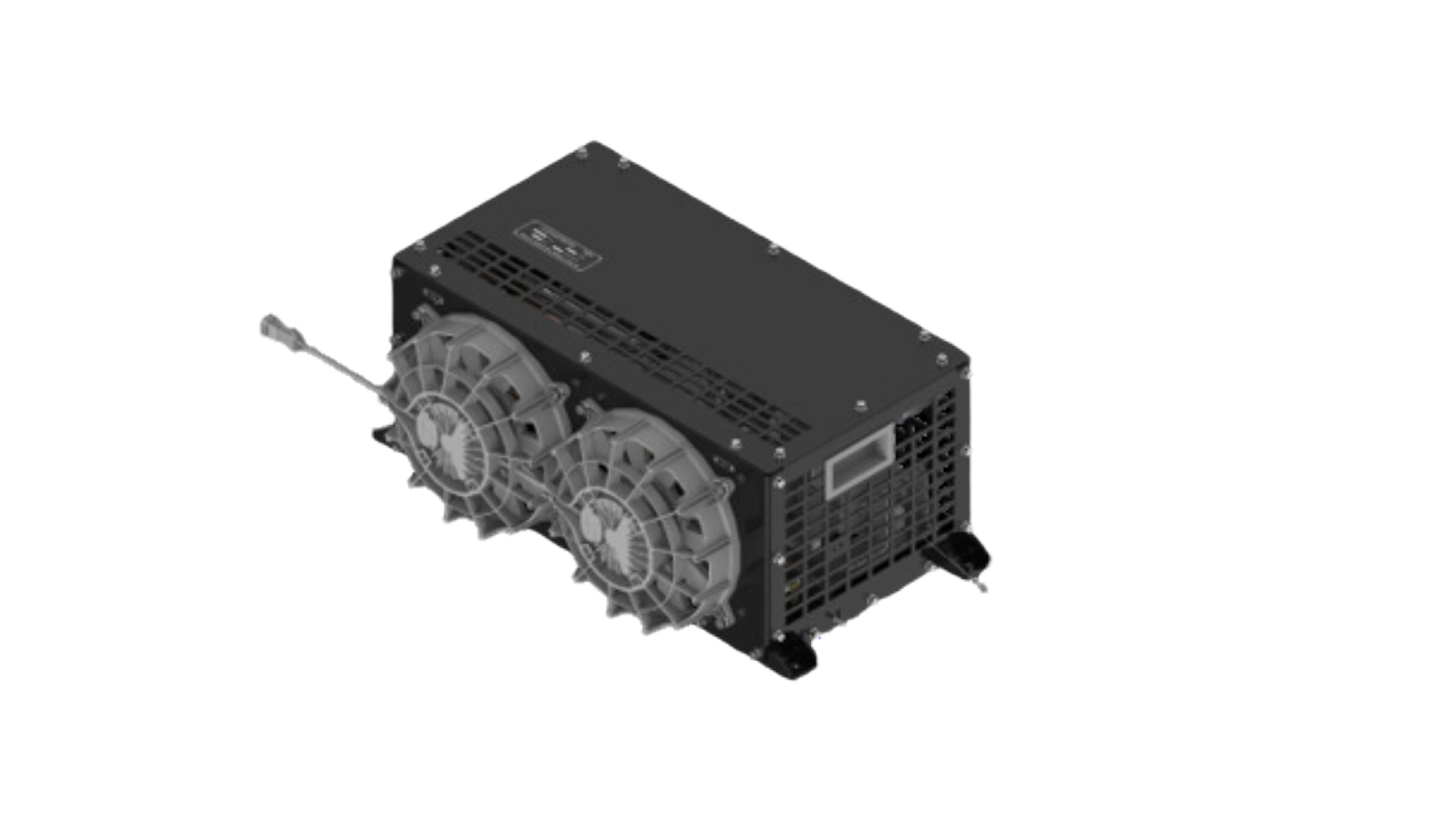

Permanent Magnet Synchronous Motor (PMSM): The motor provides high torque with peak efficiency, which is critical for optimized energy use and performance

Regenerative Braking: Captures braking energy to extend range and improve overall energy efficiency

Advanced Converter Control: Integrated Converter technology maximizes efficiency and supports smooth power delivery for diverse operating conditions

Rugged and Low-Maintenance: Built for durability, the powertrain is engineered to endure the rigorous demands of commercial applications, reducing maintenance needs

High-Precision Vehicle Control Unit (VCU): Ensures accurate propulsion control with configurable vehicle and battery parameters

Sensorless Control Technology: Facilitates efficient motor operation and enhances reliability by reducing sensor dependency

Liquid-Cooled Motor and Components: Ensures stable operation across a range of temperatures with effective cooling solutions

Modular Design for Flexibility: Allows for integration in both new electric buses and retrofit applications for existing fleets

Comprehensive Diagnostics and IoT Capability: Provides real-time monitoring and diagnostics for optimized maintenance through CAN with OBD and IoT integration

Case study gallery

Model: Volvo-Eicher 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck. Vehicle integration and mining trials are successfully completed.

Model: Mahindra 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck.

Model: Mahindra

Build and year: Battery Electric Conversion, 2023

Medha has performed the mechanical refurbishment and designed, supplied, and integrated electric powertrain and energy storage kit for the truck. Vehicle is operating successfully.

Model: HM 70 t

Build and year: Battery Electric Conversion 2023

Medha has refurbished the mechanicals, designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck. Vehicle integration and mining trials are successfully completed.