Medha’s ZEBHRA Traction Converters and Choppers are specifically designed to capture regenerative energy during braking, allowing for efficient energy recuperation. This system harnesses kinetic energy and stores it for use in auxiliaries and propulsion, significantly improving energy efficiency, reducing fuel consumption, and minimizing brake wear.

The traction converters are integrated with Traction Batteries for energy storage, and utilize Voltage Limiting Units (VLU) and Dynamic Brake Resistors (DBRs) to manage and dissipate excess energy, ensuring synchronized operation for vehicle safety.

Key Components

- ZEBHRA Converter

- Traction Battery

- Voltage Limiting Unit (VLU) and Dynamic Brake Resistor (DBR)

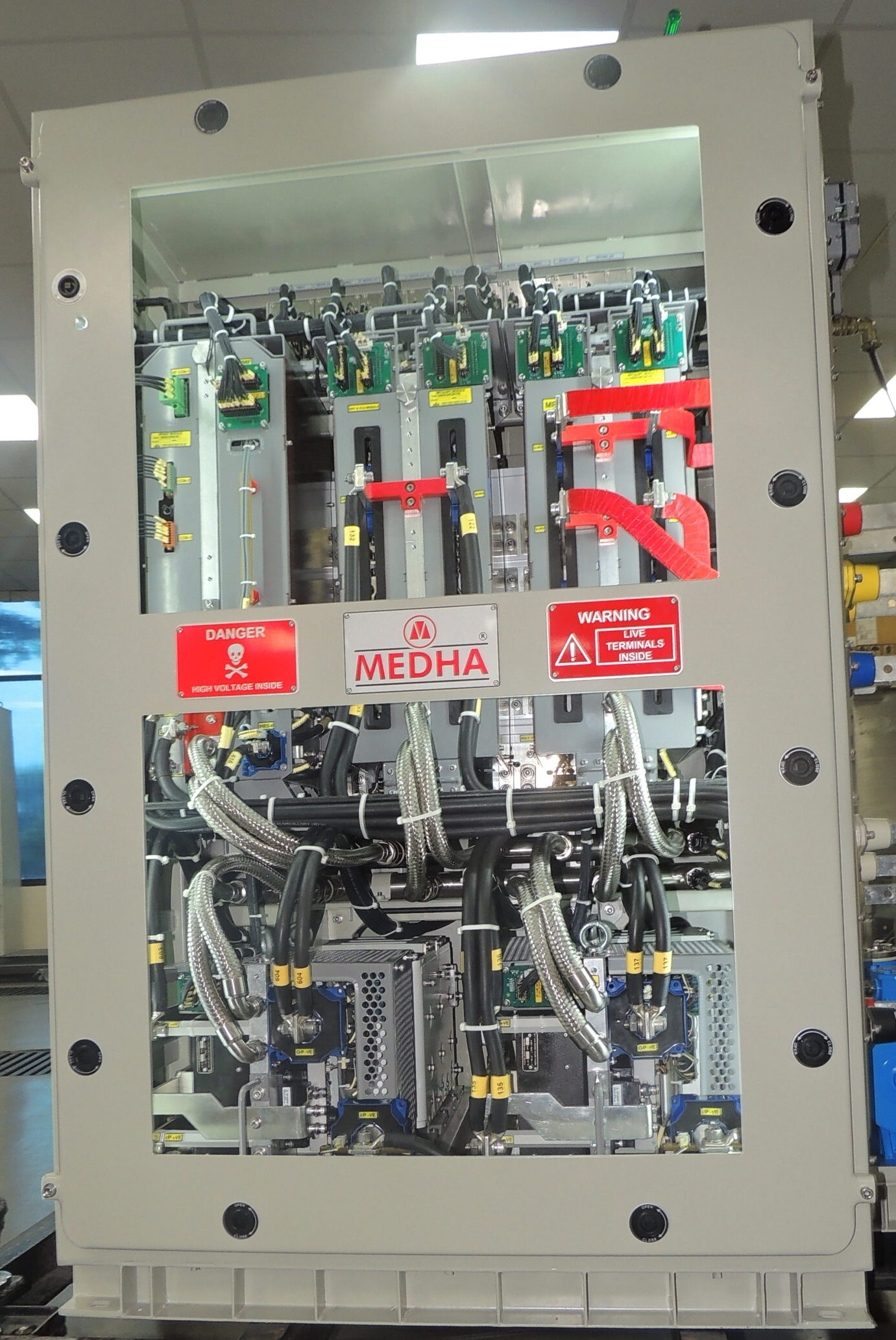

ZEBHRA Converter

The ZEBHRA Converter is a custom-built system designed for zero-emission rolling stock, capable of powering vehicles with up to six-axle configurations. This integrated converter system features multiple inbuilt converters, including:

- Generator Power Converter (GPC)

- Traction Motor Power Converters (MPC)

- Traction Battery Buck-Boost Converter (TBBC)

- Auxiliary Power Inverter (API)

- 24V DC Battery Charger (BC)

- Drive Control Electric Unit (DCU)

- Dynamic Braking Voltage Limiting Unit (VLU)

A standout feature of ZEBHRA is its SIL 2 certified traction cut-off for Motor Power Converters, providing a robust safety mechanism. The converter’s size, shape, and configuration are adaptable, allowing for customization to fit various spatial and operational requirements.

Within the ZEBHRA cabinet, IGBTs with integrated freewheeling diodes are used as active switching components. The 24 V Battery Charger employs advanced Silicon Carbide (SiC) modules for optimal performance and efficiency. All power modules share a common liquid cooling system, with temperature sensors actively monitoring each module to prevent overheating.

Each IGBT is managed by a dedicated Gate Drive (GD) card, which controls switching actions and provides protection against fault conditions, including short circuits. These GD cards interact continuously with the control computer, enhancing system protection and integrity. Independent control electronics for each converter ensure precise operation and comprehensive protection across all functions.

Compliance: ZEBHRA Converters meet stringent international standards, including EN, IEC, ERA, ERTMS, UIC, and EU regulations, making them suitable for global deployment.

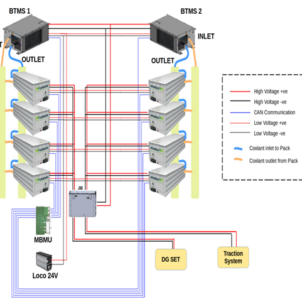

Traction Battery

Medha designs and manufactures high-performance LFP (Lithium Iron Phosphate) and LTO (Lithium Titanate) battery packs in-house, tailored to specific applications. We use Nickel Magnesium Cobalt chemistry batteries from third parties for high energy density applications. Each battery pack integrates an advanced Battery Management System (BMS) and Battery Thermal Management System (BTMS) for optimal safety, efficiency, and thermal control.

Dynamic Brake Resistor (DBR)

Medha’s Dynamic Brake Resistors (DBRs) are designed for efficient energy dissipation during braking, converting excess kinetic energy into heat. The DBRs feature a cooling blower and robust structural components, making them suitable for both new installations and retrofits. These components ensure reliable performance under varying operational conditions.

Benefits

- Energy Efficiency: Recaptures kinetic energy during braking, reducing overall energy consumption.

- Enhanced Safety: Synchronized operation with Voltage Limiting Units and DBRs ensures system stability.

- Customization: Flexible design and configuration options meet specific vehicle and application requirements.

- Global Compliance: Adheres to international standards, making it suitable for worldwide applications.

Medha’s ZEBHRA Traction Converters, integrated with advanced battery systems and braking components, provide a comprehensive solution for zero-emission, energy-efficient rolling stock, setting a new benchmark in sustainable rail transportation.