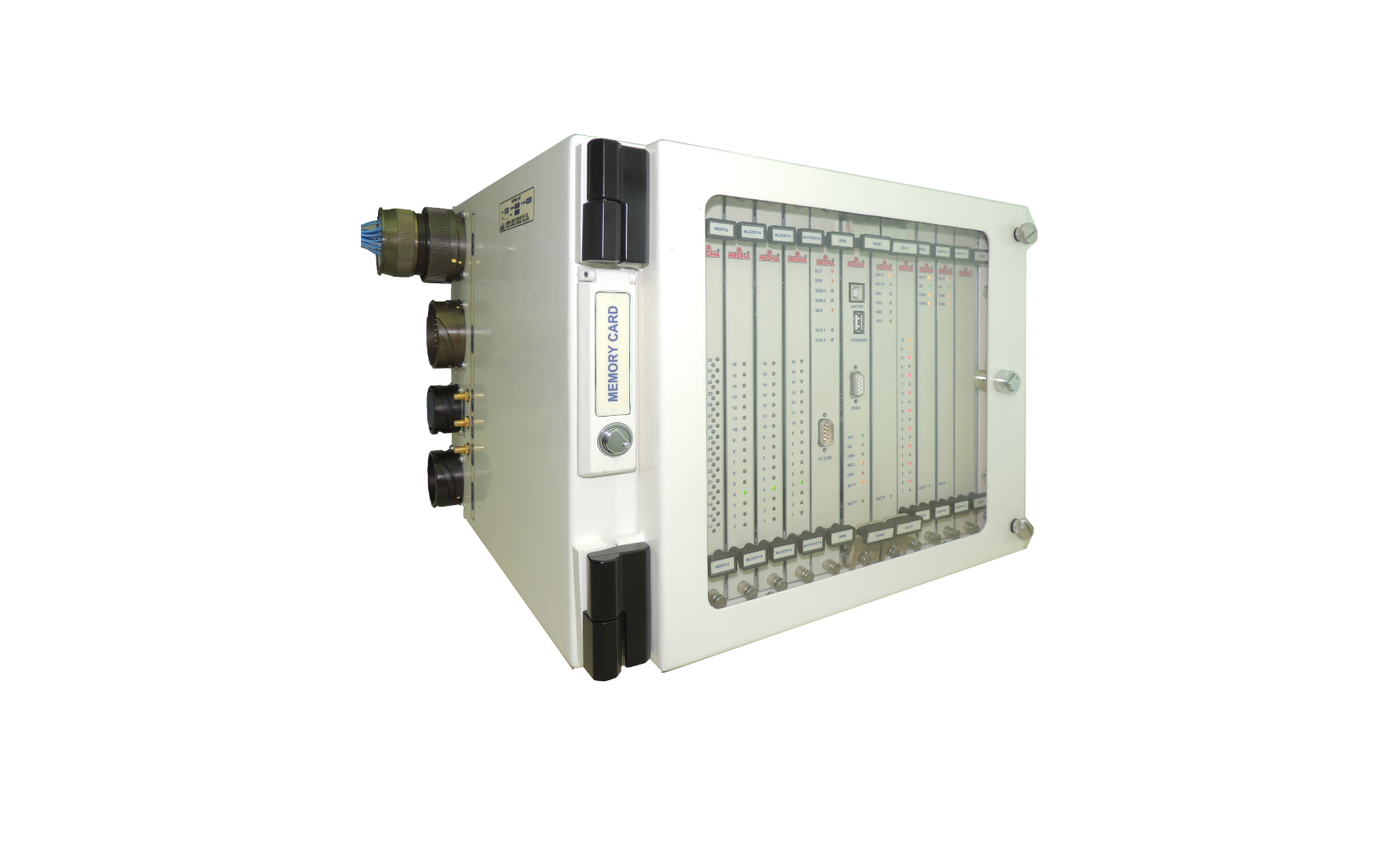

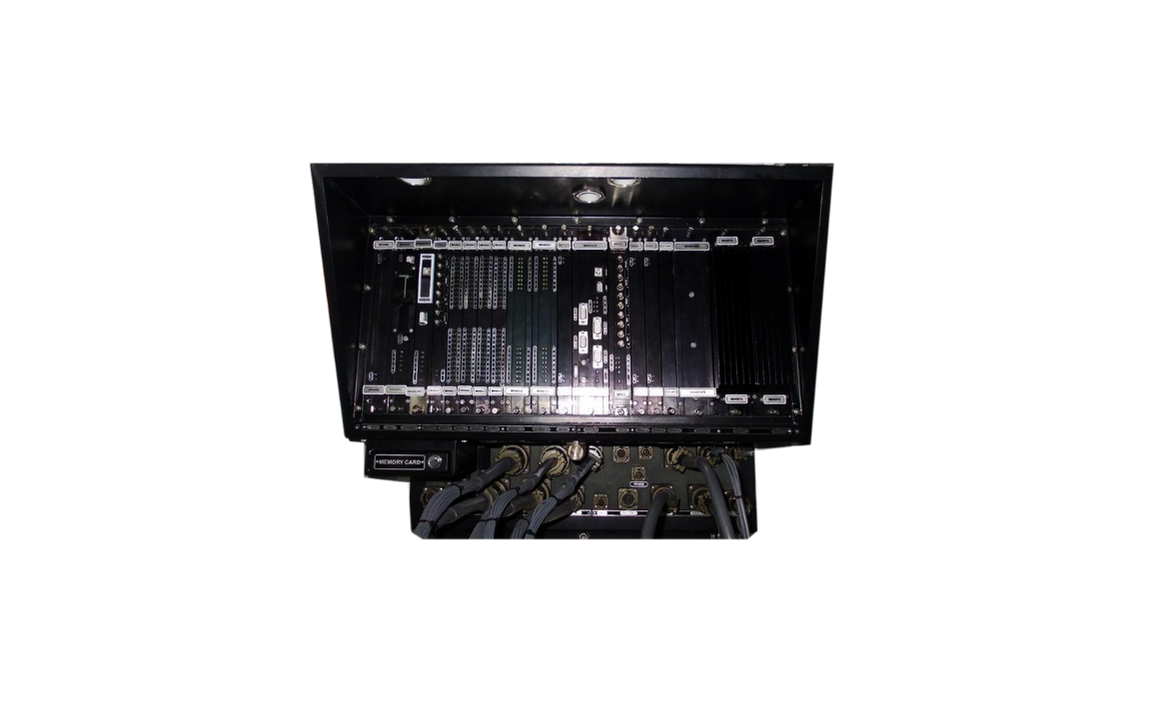

Medha’s Train Control Management System (TCMS) is a comprehensive vehicle control solution designed to efficiently monitor, control, and manage various train functions, ensuring optimal performance and reliability. The system integrates advanced control technology with user-friendly interfaces, enhancing train operations, diagnostics, and safety. Medha’s TCMS is tailored for seamless integration into all types of rollingstock.

More than 4200 TCMS units installed globally.

Key Features and Benefits

- Centralized Monitoring and Control: Provides real-time monitoring and centralized control of various onboard systems, including propulsion, braking, HVAC, lighting, auxiliaries, and doors.

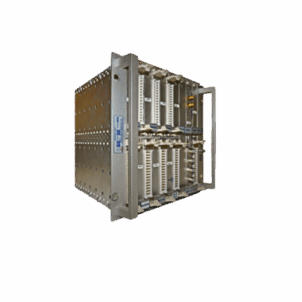

- Modular and Scalable Design: The TCMS architecture is modular, allowing easy customization and scalability to meet specific customer requirements and vehicle types.

- Enhanced Safety and Diagnostics: Features advanced fault detection and diagnostic capabilities, enabling preventive maintenance and reducing downtime.

- High Reliability and Availability: Built with redundant systems and robust components, ensuring high reliability even in harsh railway environments.

- Advanced Communication: Supports various communication protocols, such as Ethernet, CAN, and MVB.

- Compliance with Industry Standards: IEC 60571, IEC 61373 (shock and vibrations), IEC 60068 (Environment), IEC 61000 (EMC), IEC 62236-3-2 (surge, EMC, ESD, EFT).

Specifications

| Parameter | Details |

|---|---|

| System Architecture | Centralized or distributed control, modular design |

| Communication Protocols | Ethernet, CAN, MVB |

| Display Interface | HMI for operator control and monitoring |

| Fault Diagnostics | Real-time fault detection, logging, and diagnostic alerts. Monitoring of over 250 types of faults. |

| Compatibility | Supports EMUs (High speed train, Metros, Intercity), DEMUs, Locomotives, Light Rail and Monorail |

| Safety Standards | Compliant with relevant international railway standards |

| Operating Temperature | Designed to operate reliably in extreme environmental conditions |

| Redundancy | In-built redundancy for critical components and subsystems |

Add on features

- Vehicle remote monitoring

- Fuel savings solutions

- Distributed power control integration for a multi-locomotive consist

- Fuel level sensors

- Auto creep control, and many more