MEP™ is a state-of-the-art, retrofittable upgrade for legacy DC traction locomotives equipped with DC Generator or Alternator Excitation Control.

It replaces traditional, slower-responding analogue relay-based controls with high-speed microprocessor-based digital control.

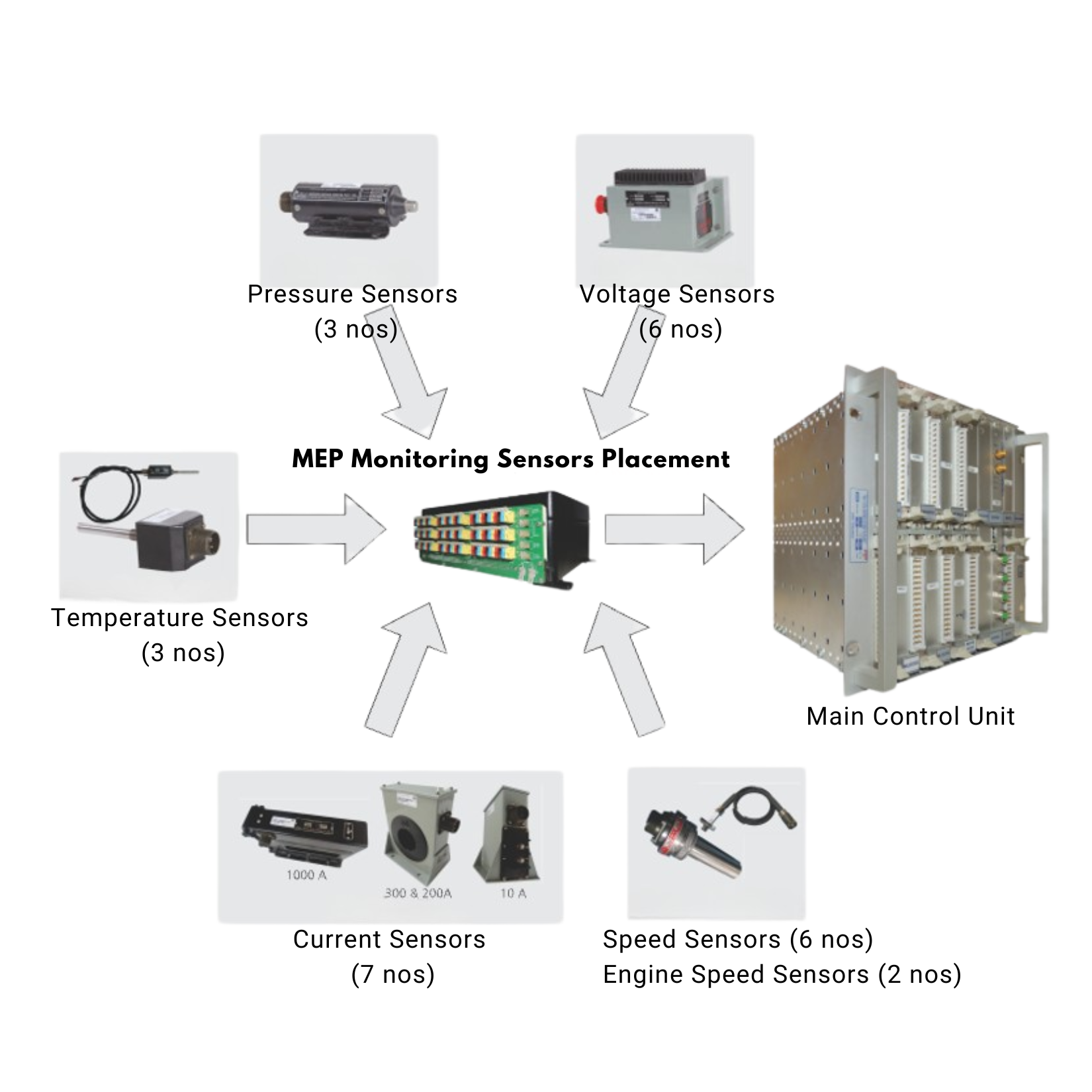

The MEP™ solution incorporates 26 newly added sensors that measure critical parameters previously unavailable in legacy systems.

By combining high-speed digital control and precise real-time measurement, MEP™ delivers:

- Up to 20% higher haulage capability

- Up to 10% fuel savings

- Improved traction performance, equipment protection, and reliability

The result: smarter control, better efficiency, and a major leap forward in modernising existing locomotive fleets — already proven across 5,000+ locomotives worldwide.

What is MEP™

The Microprocessor Engine and Propulsion Control System (MEP™) is a 32-bit, high-performance platform that replaces conventional electro-mechanical excitation systems. It delivers complete traction, propulsion, and engine control for DC-traction locomotives with intelligent diagnostics, advanced fault protection, and real-time monitoring.

Conventional systems depend on slow relay logic and manual adjustments that restrict performance.

MEP™ introduces adaptive digital control that reacts instantly to load, slip, and traction variations—delivering higher reliability and operational efficiency.

Why Upgrade to MEP™

-

Higher Haulage: Boosts tractive effort by up to 20%.

-

Fuel Efficiency: 6–10% reduction in fuel consumption.

- Integrated AESS: Built-in Auto Engine Start/Stop—no separate unit required.

-

Better Adhesion: Up to 45% improvement with intelligent slip detection and automatic sanding.

-

Extended Equipment Life: Protects alternators, traction motors, and auxiliaries from overloads.

- Reduced Maintenance: Logs 250+ fault types with modular, plug-in assemblies for quick service.

How the MEP™ Works

At the heart of MEP™ is a digital control unit that continuously monitors locomotive performance through a network of sensors.

-

Sense: Collects data from traction motors, alternators, temperature, and pressure sensors.

-

Decide: Processes these inputs using real-time control algorithms to maintain optimal excitation and traction.

- Act: Adjusts power delivery, manages braking transitions, and safeguards critical components.

This closed-loop control ensures precise traction management, faster slip recovery, and smooth transitions across varying loads.

System Architecture

The MEP™ package includes everything needed for full locomotive integration:

-

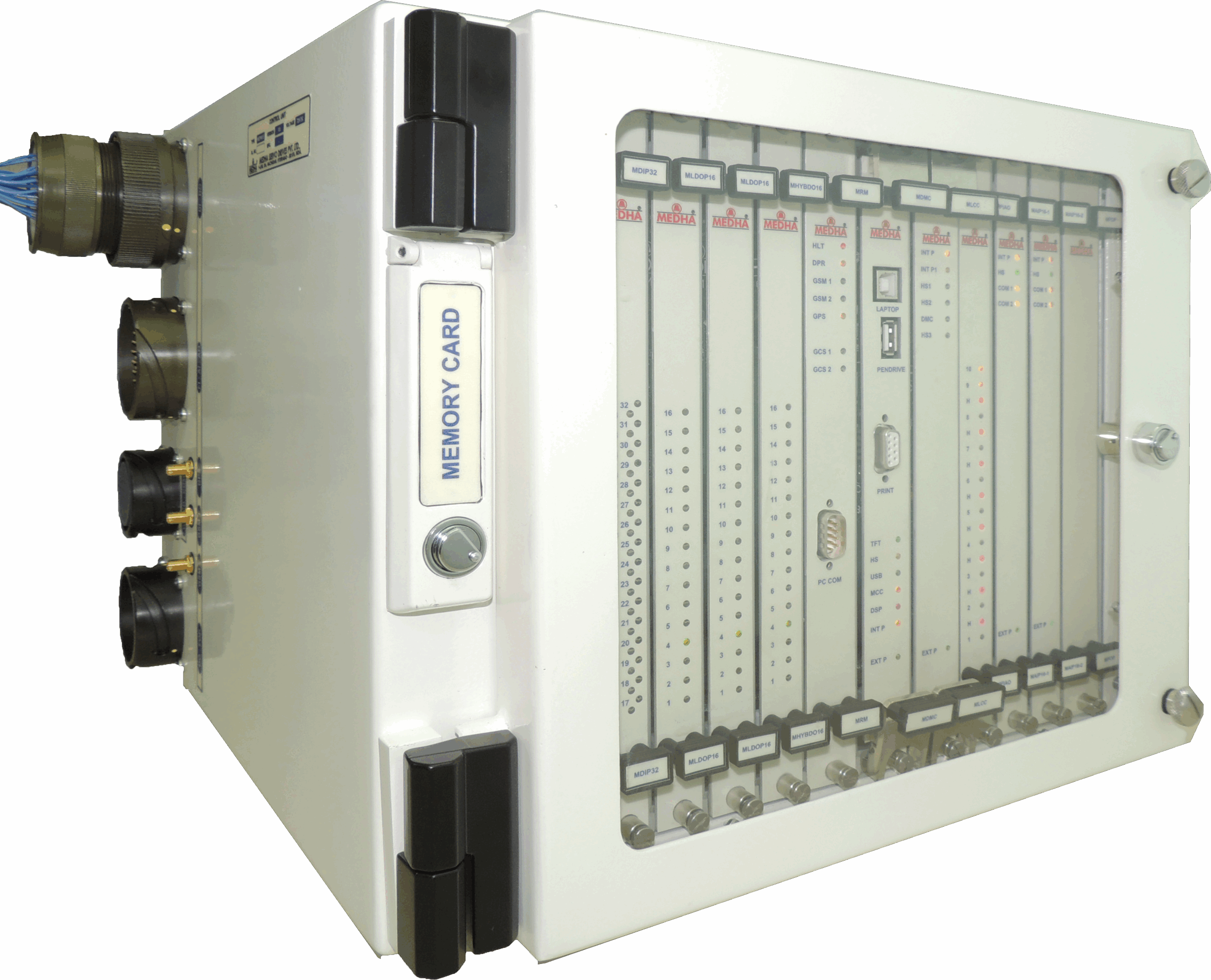

Main Control Unit: Modular plug-in cards for easy maintenance and quick replacement.

-

Driver Display (TFT/VFD): Displays traction, engine, and diagnostic data in real time.

-

Sensor Suite: Monitors current, voltage, temperature, and traction motor speed.

-

Remote Monitoring (LocoNet™): Enables cloud-based fleet analytics, GPS tracking, and remote diagnostics

Key Advantages

-

Real-time digital excitation and propulsion control

-

Intelligent traction motor isolation—keeps locomotive operational even with up to five defective motors

-

Automatic wheel-diameter calibration and locked-axle detection

-

Extended battery and blower life through smart load management

-

Predictive maintenance via continuous monitoring and fault logging

Specifications

| Parameter | Details |

|---|---|

| Supply Voltage | 74 VDC nominal (20–130 VDC) with full electrical protection. |

| Mode | Constant HP operation with inbuilt load control. |

| Slip Detection | Through traction motor RPM sensors. |

| Fault Diagnostics | Real-time fault detection, logging, and diagnostic alerts. Monitoring of over 250 types of faults. |

| Display | TFT touch or VFD. |

| Communication | USB (configuration/data), CAN, RS-485. |

| Diagnostics | Fault logging with timestamps; self-test and load-box testing. |

| Traction Alternator Control | PWM-based digital excitation with full galvanic isolation and fault protection. |

Global Deployments

With over 5,000 installations worldwide, MEP™ powers locomotive fleets across India, the USA, Africa, and Southeast Asia — delivering reliability and performance on models such as EMD GT46-MAC, GE U20C, ALCO YDM4, GE Class 88, and AD3400