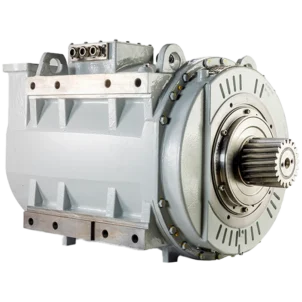

Head-End Power is a system of electrical power distribution on a passenger train consist driven by a locomotive in which a power source in a central location on the train; either at the head end in the locomotive or a generator car. It generates all the electricity for non-traction power needed by the train.

Medha’s Head End Power (HEP) units are designed to supply auxiliary power to an entire train, covering essential systems such as lighting, fans, HVAC, heating, and battery charging.

Features

| Feature | Details |

| Power Range | Medha provides HEP units with power ratings from 300 kVA to 500 kVA.

For higher power needs, configurations up to 1000 kVA (using two 500 kVA units) are also available. |

| Auxiliary Power Supply | These HEP units utilize the capacities of the alternator or transformer onboard to generate power for auxiliary train loads. This includes critical functions like lighting, fan operation, air conditioning (HVAC), heating, and battery charging for the entire train. |

| IGBT-Based Technology | Medha’s HEP units use IGBT (Insulated Gate Bipolar Transistor) technology for efficient power conversion. The output of the inverter includes sine filters, which help reduce harmonic distortions, ensuring cleaner and stable power. |

| Protection Features | Built-in protections against output overload, short circuits, and power grounding faults are included to enhance reliability and safety. |

| Versatile Design | The converters are designed to work with a wide range of input sources, allowing them to be adapted to different train configurations and power systems. |

Key Features

- Multiple Voltage Options: Available in single, dual, or multi-voltage configurations to meet different power requirements.

- Energy Efficiency: Designed with a focus on optimizing energy use.

- Built-in Redundancy and Safety: Enhanced safety features ensure continuous operation even if one part of the system fails.

- Flexible Mounting Options: Can be mounted under the train (underframe) or onboard, based on space and design constraints.

- Cooling Options: Available with natural air cooling, forced air cooling, or liquid cooling, depending on the application needs.

- Modular Design: The units are modular, making them easy to maintain and service.

- Durable and Compact: Engineered to be reliable and robust, capable of withstanding harsh railway conditions.

- Compliance with Standards: Meets international standards including IEC 60571, IEC 61287, and IEC 61373 for electronic equipment in rail applications.

Flexible Integration

Medha’s HEP units can be customized to suit specific customer needs, including:

- Integrated Battery Charger: Option to combine HEP units with an in-built battery charger.

- Integration with Traction Converter: HEP unit can be integrated with the traction converter to streamline power systems.

- Customer-Specific Configurations: Tailored solutions based on specific project requirements.

This comprehensive design and flexibility make Medha’s HEP units ideal for meeting the auxiliary power demands of modern rail vehicles.