Medha group’s (Enika) Hydrogen Bus project completed a significant milestone by commencing its passenger service in Gdańsk in early May 2024. Gdańsk is a port city on the Baltic coast of Poland. Enika is the bus system integrator and have designed, manufactured and integrated all power electronic and control devices enabling optimal operations.

The Hydrogen fleet known as Nesobus can travel around 450 km on a single tank with refuelling taking just 15 minutes. Average daily distance urban buses travel in Gdańsk is around 250 km. Another 10 new Hydrogen buses will join the fleet this year.

Braking resistor: The RBTD.60kW.2R5-19920 braking resistor is essential for managing the bus's kinetic energy during braking.

Drive auxiliary box: The ENI-AUX_BOX/K3 houses various electronic components and controls for the drive system.

Battery current sensor: The 24V ENI-BCM board battery current sensor monitors the battery's performance.

Communication supervisory system: The ENI-VCCU SWITCH.3 system ensures seamless communication between the bus and the charging infrastructure, complying with ISO 15118 and DIN 70121 standards.

Charging visualization system: The CCS2 ENI-VCCU DISPLAY.1 system provides real-time information on the bus's charging status.

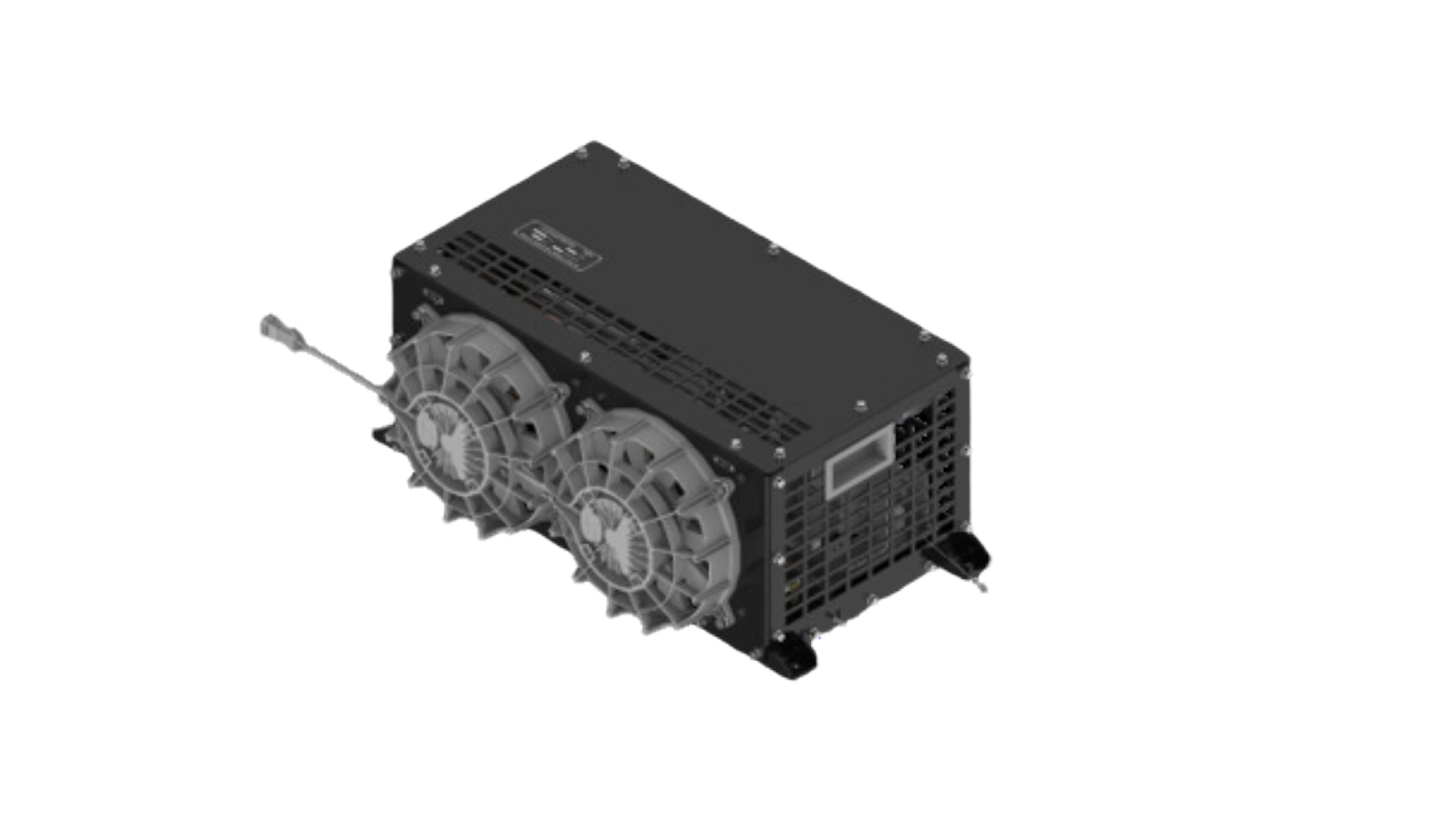

Hydrogen cell DC/DC converter: The ENI-PH2/70 converter efficiently converts DC power from the hydrogen fuel cells.

Diagnostic connector: The ENI-P3CANv3 diagnostic connector allows for easy troubleshooting and maintenance.

Hydrogen cell handling devices: Enika has also provided necessary devices for handling and managing the hydrogen fuel cells.

Medha group’s expertise in electric vehicle systems has been instrumental in the successful integration of these components into the Nesobus hydrogen buses. As a system integrator, Medha has ensured the seamless operation of the entire drive system, enabling the buses to deliver exceptional performance and efficiency.

Medha group’s hydrogen buses are paving the way for a cleaner and more sustainable future. By replacing traditional diesel-powered buses with hydrogen fuel cell vehicles, we can significantly reduce greenhouse gas emissions, improve air quality, and create a more environmentally friendly transportation system. Hydrogen buses offer numerous advantages, including zero tailpipe emissions, reduced noise pollution, longer operating ranges, and faster refueling times compared to electric buses powered by batteries. As cities and countries seek to transition to cleaner forms of energy, hydrogen buses are emerging as a promising solution for public transportation.

More Zero Emission Bus case studies.

Model: Urus 12 m City Buses

Build and year: OEM New, 2018

Medha group (Enika) designed, manufactured, and delivered complete powertrain systems for 12 m URSUS City Smile 12LFE electric buses. These buses are now in operation in Zielona Góra and Szczecinek, Poland.

Model: Veera 13.5 m Airport Bus

Build and year: OEM New, 2024

Medha has designed, supplied and integration of complete electric powertrain and energy storage and management kit in to the bus. Buses operate 22 h a day with a short period for recharging. LTO batteries are thus used for achieving fast charging.

Model: Autosan 12 m City Buses

Build and year: OEM New, 2021

Medha group's (Enika) drive systems have contributed to the successful operation of the Autosan Sancity 12LFE electric buses. These vehicles have demonstrated impressive range and efficiency, traveling nearly 400 km on a single charge without recharging.

Model: Autosan 10 m City Buses

Build and year: OEM New, 2023

Medha group (Enika) delivered advanced drive systems for the Autosan Sancity 10LFE electric buses. These systems enhanced performance, efficiency, and sustainability. Key features include a powerful motor, liquid-cooled inverter, battery management, and user-friendly interface.

Model: EKOVOLT 12 m City Bus

Build and year: OEM New, 2018

Medha group (Enika) designed, manufactured, and delivered a complete electric drive system for a 12 m EKOVOLT electric bus equipped with a central motor. The system included a synchronous traction motor and other integrated components. The bus was also fitted with a pantograph charging system

Model: Electron 12 m City Bus

Build and year: OEM New, 2018

Medha group (Enika) manufactured and delivered a complete drive system for the prototype 12 m ELECTRON electric bus. Powered by a ZF AVE-130 axle with dual high-speed asynchronous motors, the bus features individual wheel drive.

Model: Solbus

Build and year: Diesel to Battery Hybrid Conversion, 2021

Medha group (Enika) completed a challenging project to modernize Solbus gas-electric hybrid buses. Our expertise in hybrid vehicle technology has been instrumental in transforming the Solbus hybrid buses into more reliable, efficient, and comfortable vehicles.