Battery Electric Locomotive

Battery Electric locomotives (BELs) use on board battery storage to power the traction motors to propel the train. Medha offers new Battery Electric Locomotives, and is a pioneer in conversion of legacy Diesel locomotives with either DC or AC traction motors to Battery Electric.

The selection of battery chemistry, and thus the balance between energy and power density, is determined by the locomotive’s operational requirements and its application. For example, freight locomotives prioritize high energy density to support long-distance travel, while passenger locomotives demand high power density for frequent start-stop operations. Medha’s advanced electric propulsion technology is designed to adapt seamlessly to future advancements in battery technology, ensuring long-term compatibility and efficiency.

Medha has BEL solutions for applications such as small industrial locomotives, shunters, intermodal, and heavy haul.

Solutions for a wide variety of applications: Industrial, shunting, intermodal and heavy haul

Zero-Emission Compliance: For new locomotives, and fully battery-powered for existing rollingstock, reducing emissions and environmental impact.

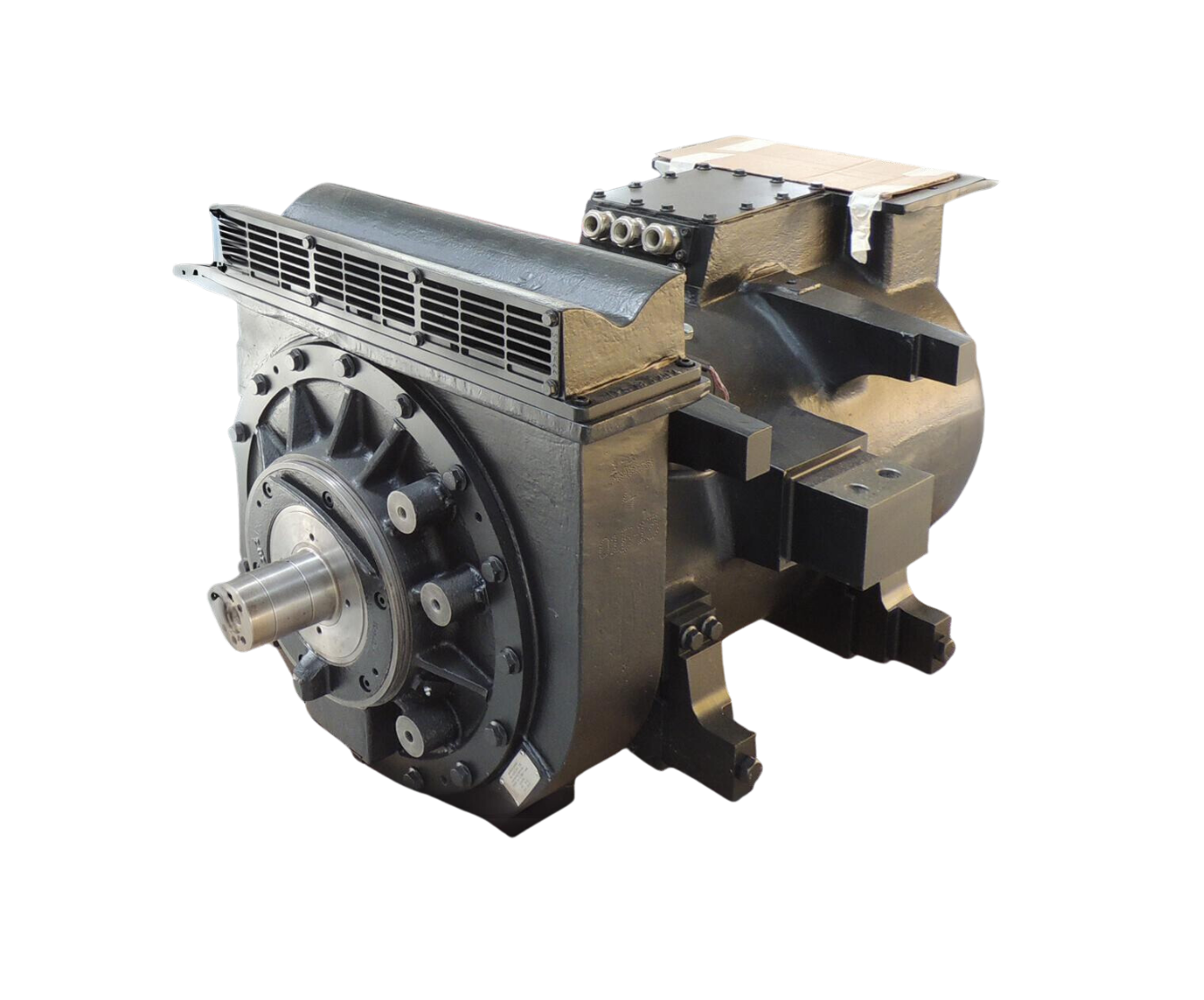

High Horsepower and Haulage Capacity: Maintains improved power and traction to traditional diesel locomotives, making it suitable for demanding applications.

Regenerative Braking: Captures and stores braking energy to improve efficiency and operational range.

Battery Thermal and Health Management: Integrated systems monitor and manage battery temperature and health, ensuring reliability and longevity.

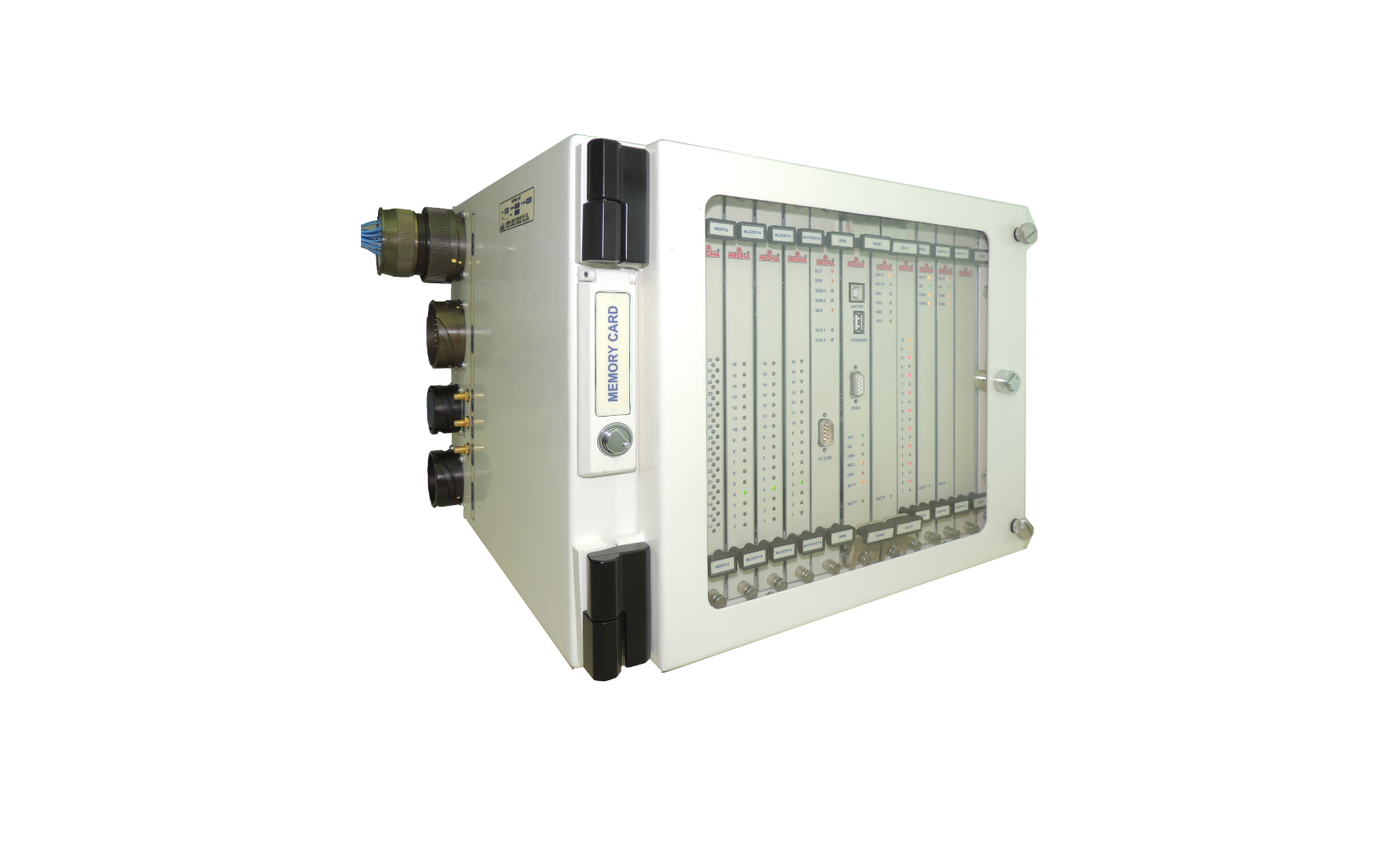

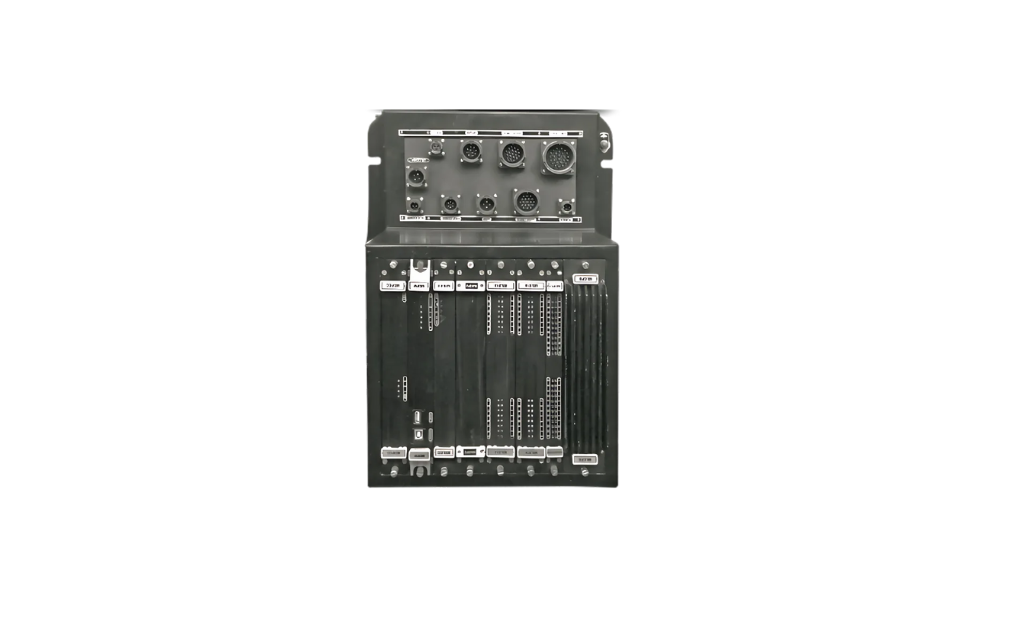

Remote Monitoring and Diagnostics: Provides real-time data, fault diagnostics, and self-diagnostics to streamline maintenance and prevent downtime.

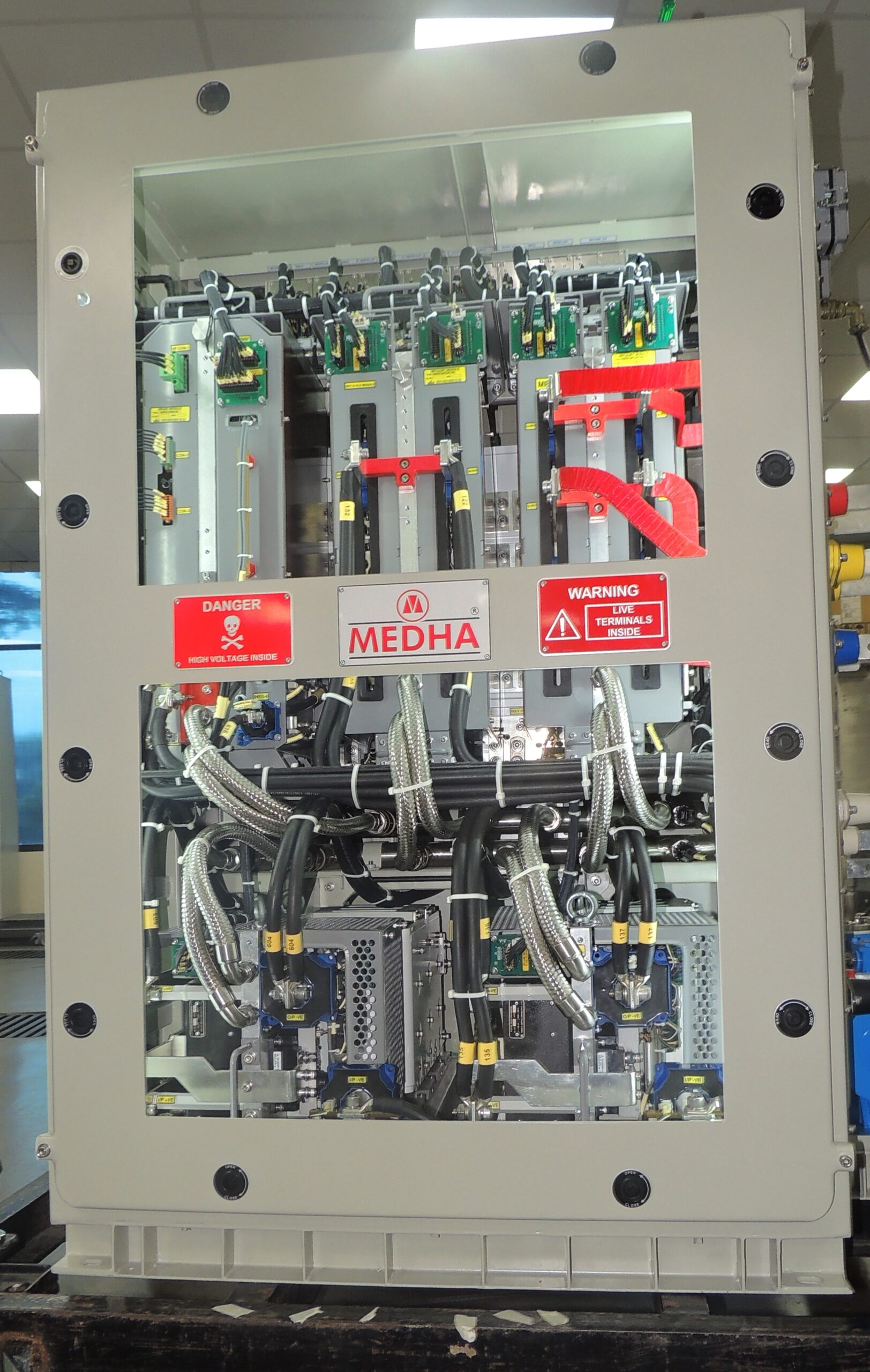

Modular Design: Includes pre-assembled components like battery banks and control systems, simplifying installation and adaptability.

Electrically Driven Components: Electric compressors and traction motor blowers reduce the reliance on moving parts, improving overall efficiency and reducing maintenance needs.

Driver-Friendly Design: Provides a familiar driving experience similar to diesel locomotives, with added comfort features. Enables seamless change management.

Flexible and Scalable: Capable of converting any configurations, 4-axle and 6-axle locomotives, with adjustable battery and charger sizes based on operational needs.

Extended Warranty and Support: Medha offers extensive warranty terms to cover the useful life of the locomotive, providing long-term support against technological obsolescence.

One-stop-shop: Entire suite of technology is designed and manufactured inhouse to EN and IEC standards to be fit to use globally

Case study gallery.

Model: GP9

Type: Diesel Electric to Battery Electric Conversion

Speed: 35 km/h

Power: 2000 hp battery equivalent

Build: Zero emission conversion

Nos: 1

Model: Watco

Type: Diesel Electric to Battery Electric Conversion

Speed: 35 km/h

Power: 2000 hp battery equivalent

Build: Zero emission conversion

Nos: 2

Model: G6 (3 Axle)

Type: Diesel Hydraulic to Battery Electric Conversion

Speed: 100 km/h

Power: 670 kW

Build: Zero emission conversion

Nos: 1

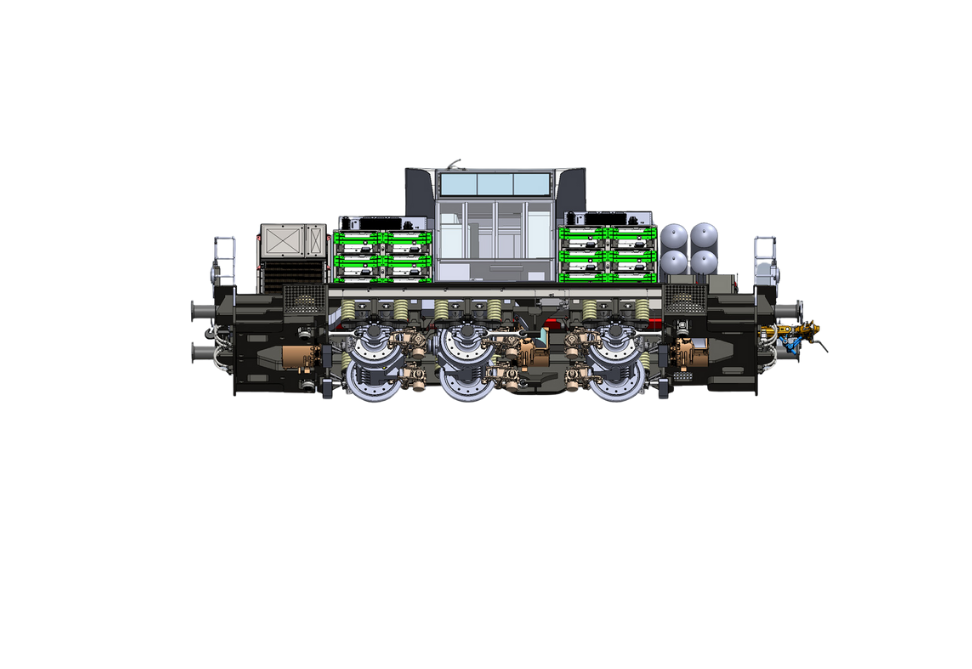

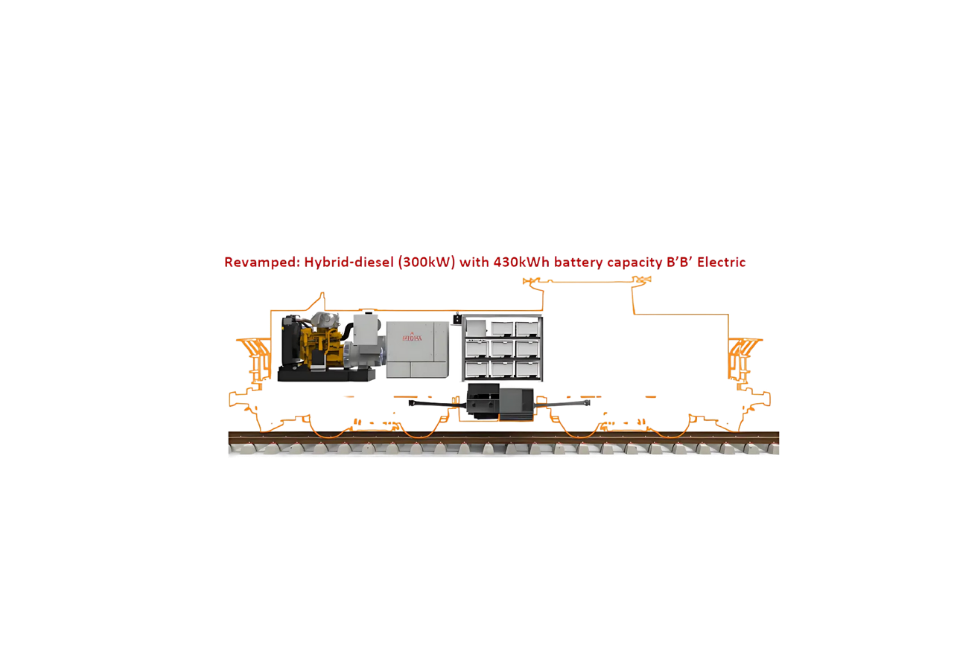

Model: Restoration (4 Axle)

Type: Diesel Hydraulic to Battery Hybrid Conversion

Speed: 100 km/h

Power: 730 kW

Build: Hybrid conversion

Nos: 1