Tarmac Buses

Electrifying tarmac buses at airports is a significant step towards reducing emissions, improving air quality, and enhancing operational efficiency. By transitioning to electric buses, airports can substantially lower their greenhouse gas emissions, minimize local air pollution, reduce noise levels, and achieve cost savings in fuel and maintenance. The tarmac vehicles usually have very low down time for charging. Medha offers a complete Battery Electric kit for tarmac buses with quick charging capabilities, as well as fast DC chargers. Battery electric tarmac buses that Medha has collaborated to build are successfully operational at Bangalore airport with more deliveries to follow.

Features.

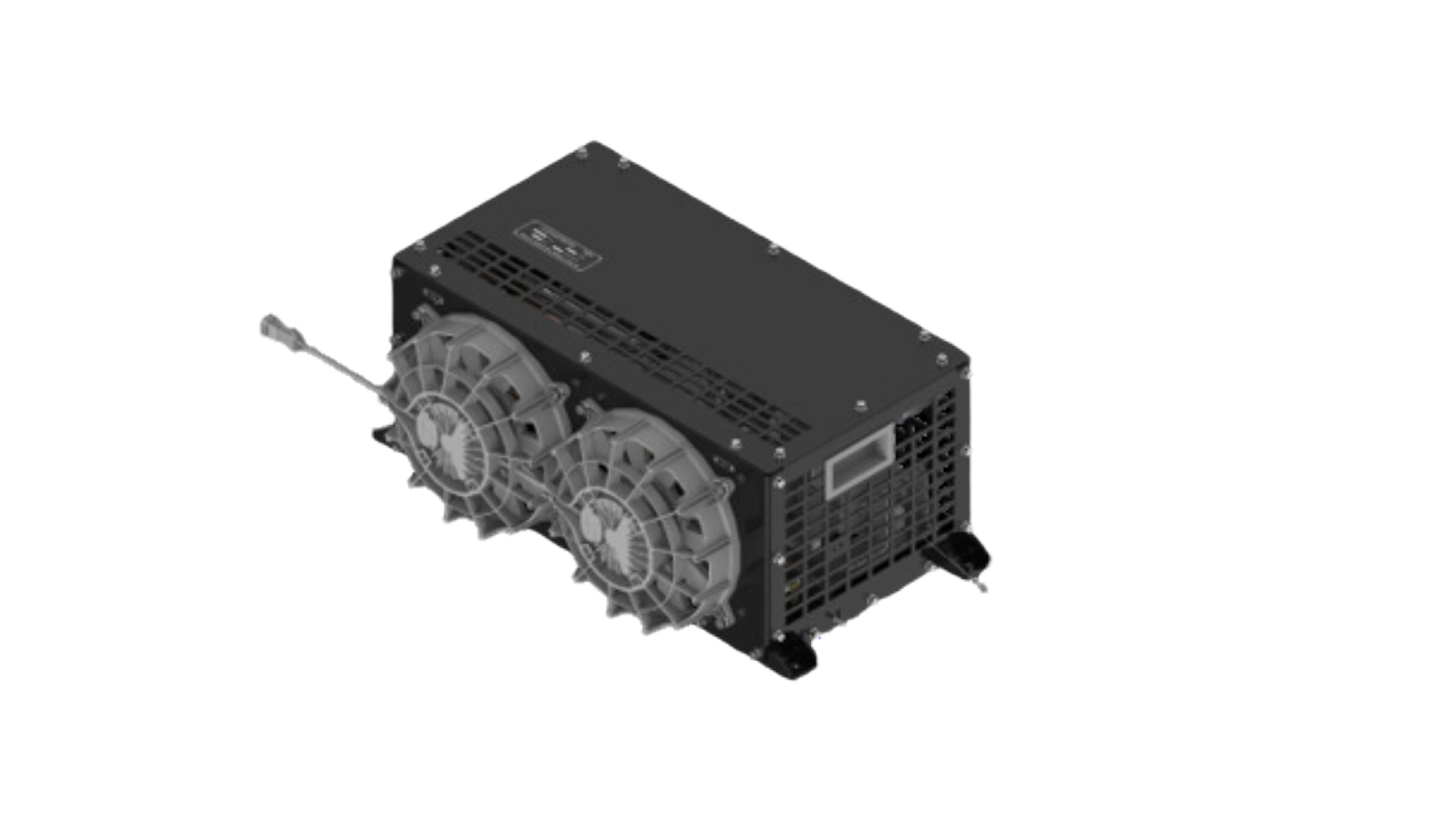

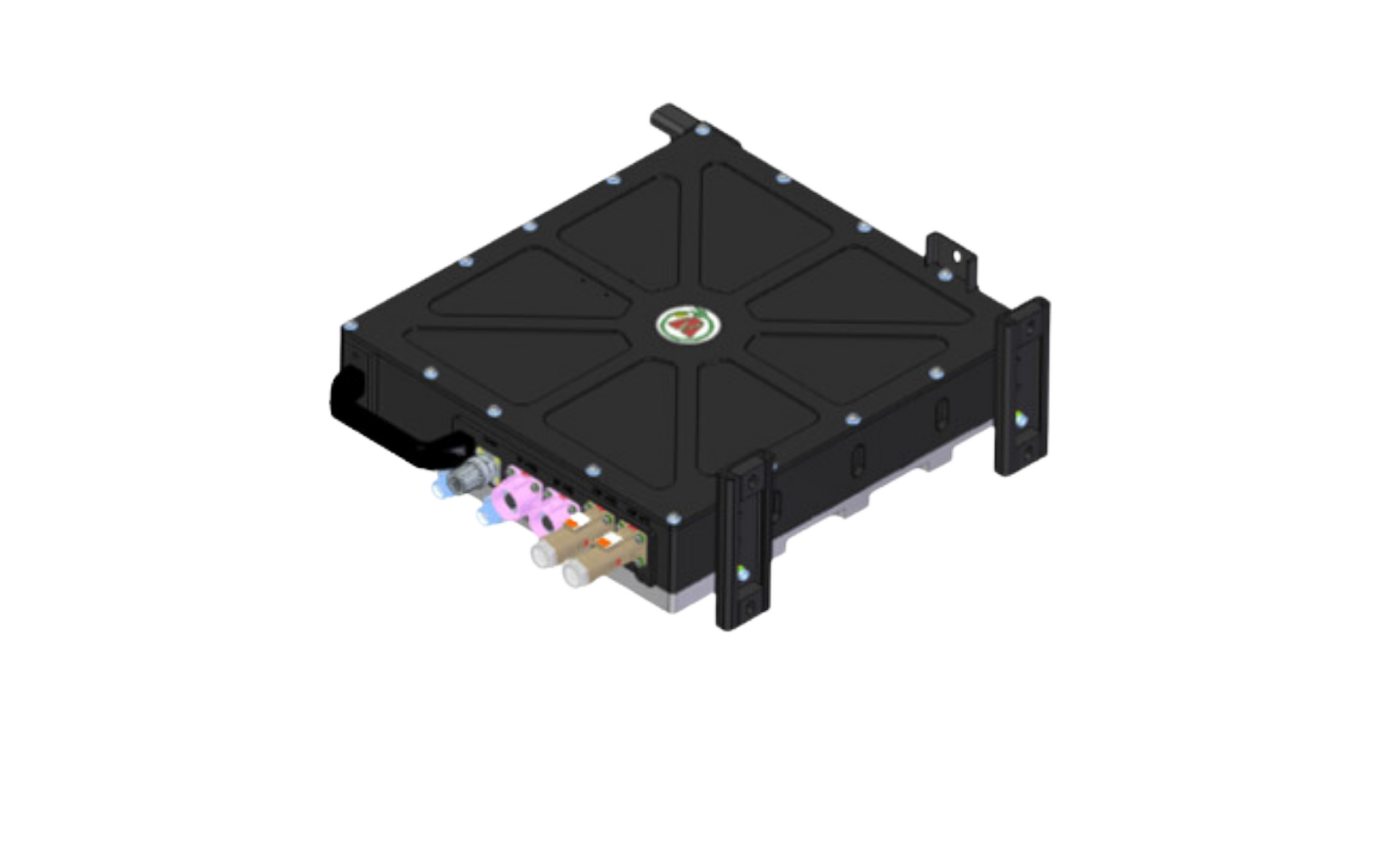

Integrated Electric Powertrain: Medha offers a complete powertrain solution, including the battery pack, designed for medium and heavy commercial vehicles

Permanent Magnet Synchronous Motor (PMSM): The motor provides high torque with peak efficiency, which is critical for optimized energy use and performance

Regenerative Braking: Captures braking energy to extend range and improve overall energy efficiency

Advanced Converter Control: Integrated Converter technology maximizes efficiency and supports smooth power delivery for diverse operating conditions

Rugged and Low-Maintenance: Built for durability, the powertrain is engineered to endure the rigorous demands of commercial applications, reducing maintenance needs

High-Precision Vehicle Control Unit (VCU): Ensures accurate propulsion control with configurable vehicle and battery parameters

Sensorless Control Technology: Facilitates efficient motor operation and enhances reliability by reducing sensor dependency

Liquid-Cooled Motor and Components: Ensures stable operation across a range of temperatures with effective cooling solutions

Modular Design for Flexibility: Allows for integration in both new electric buses and retrofit applications for existing fleets

Comprehensive Diagnostics and IoT Capability: Provides real-time monitoring and diagnostics for optimized maintenance through CAN with OBD and IoT integration

Case Study gallery.