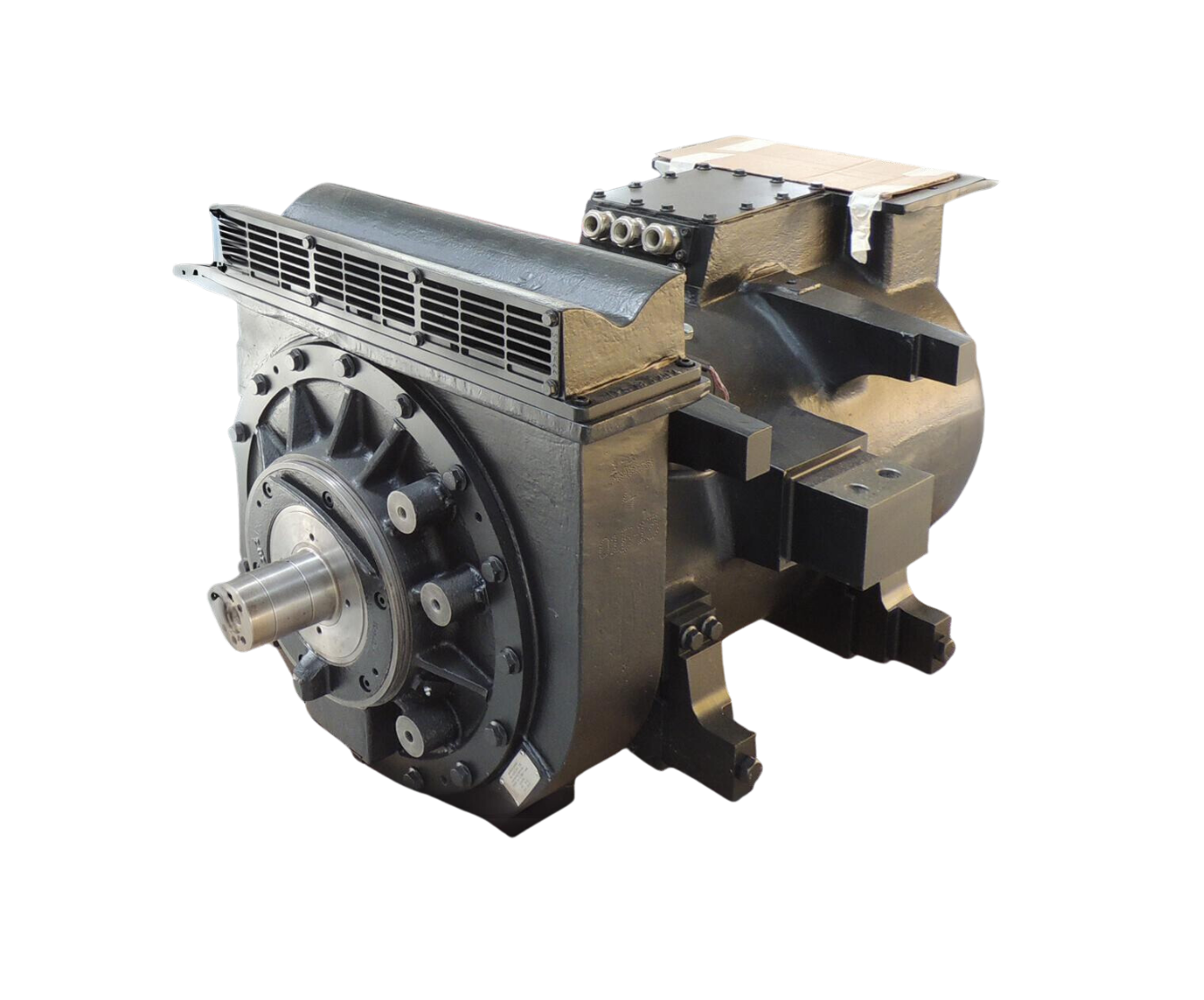

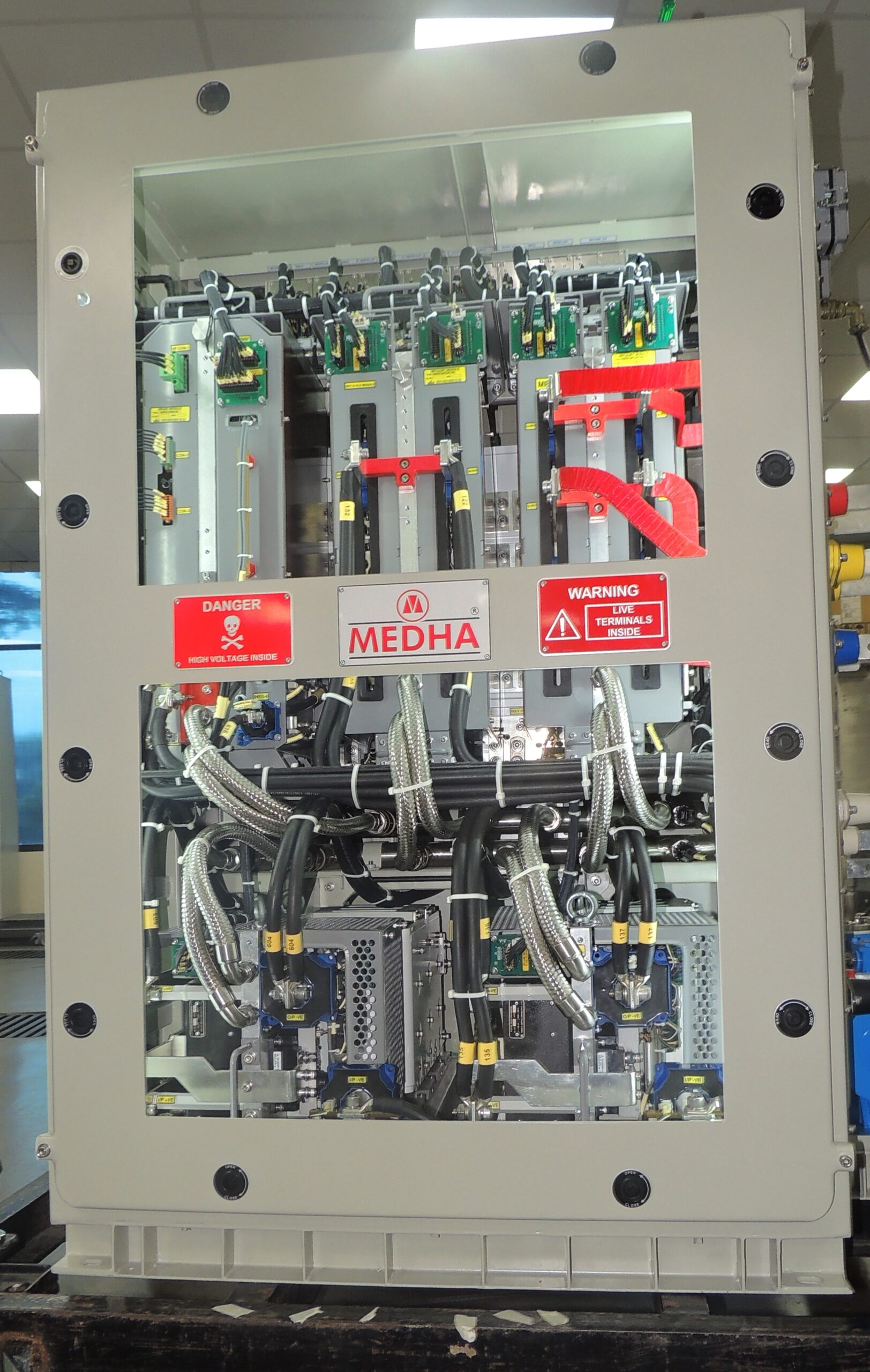

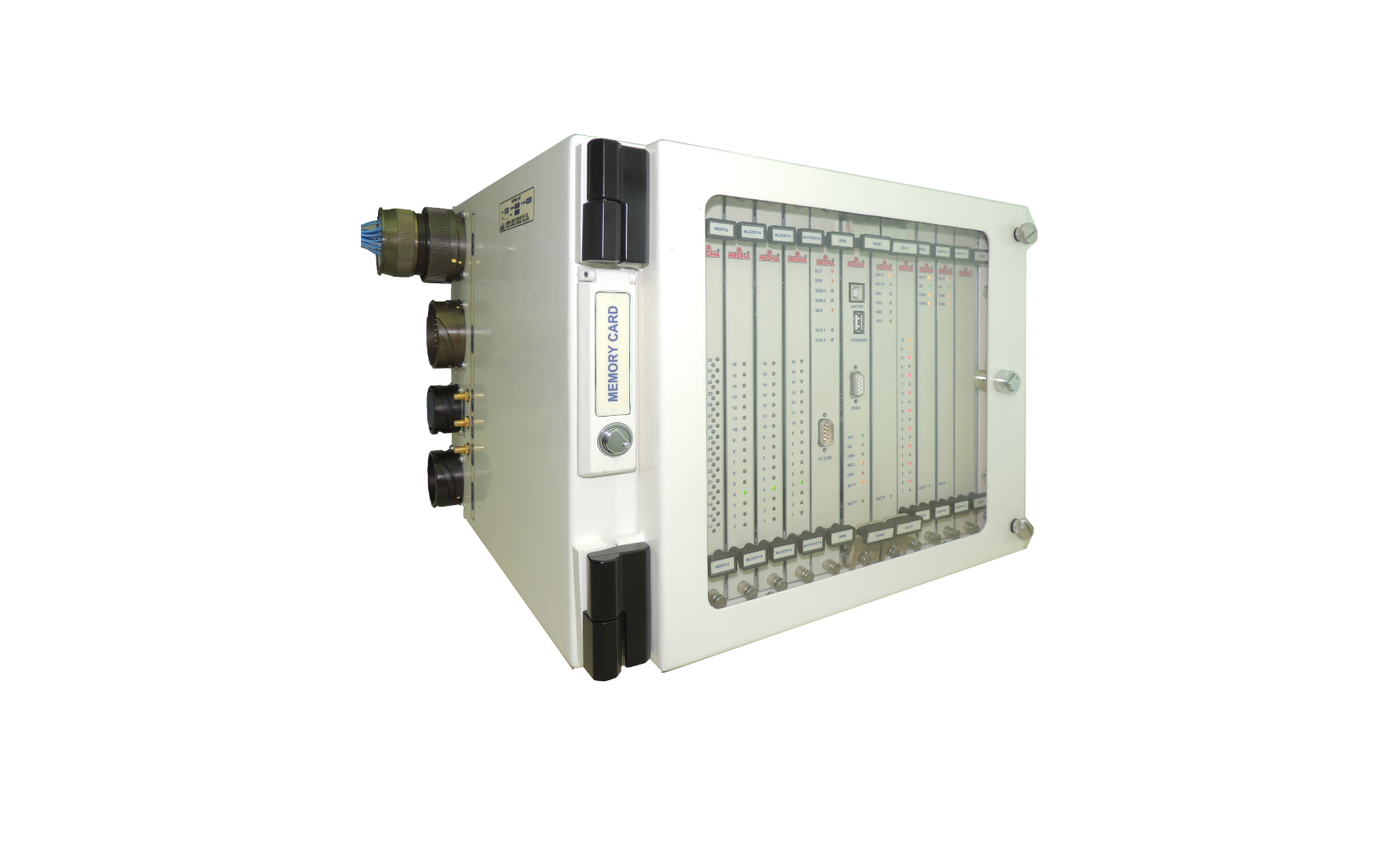

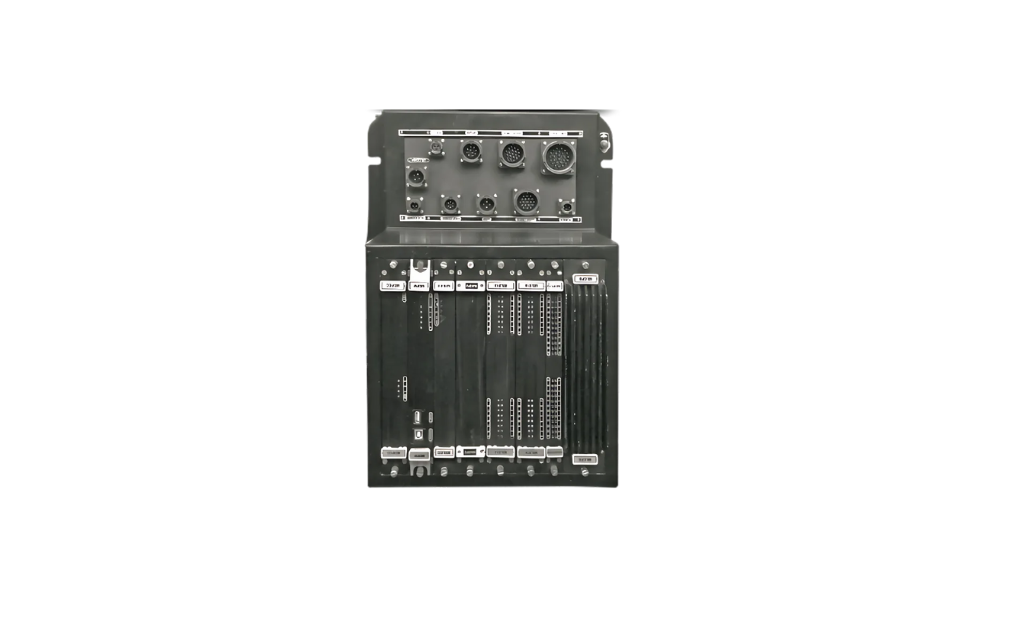

Medha’s journey toward decarbonization has been a natural progression, building upon our established, advanced suite of electric propulsion systems covering the full range from shunting to heavy-haul locomotives. With proven expertise in both electric and diesel-electric locomotives, the shift to battery-electric technology required only a change in power source — the battery — while all other core components remained a constant.

Medha’s purpose-built ZEBHRA Converters for zero-emission rolling stock, featuring inverters and Traction Buck Boost Converters, enable seamless integration of batteries as the new power source. Battery chemistry is carefully selected to balance energy and power density, tailored to specific operational demands: freight locomotives prioritize energy density for extended range, while passenger locomotives require power density for frequent start-stop operations.

In July 2023, the conversion of the EMD GP9 locomotive marked a key milestone in this journey. Since then, the battery-electric locomotive has exceeded expectations in operational efficiency, charging performance, driver comfort, and emissions elimination, setting a new standard in sustainable rail innovation.

Conversion parameters: 2000 hp battery equivalent, 2000 t haul capacity on a level grade, 35 km/h operational speed

Diesel saved: 11,356 litres (3000 gallons)

Lube oil saved: 1500 litres (400 gallons)

Coolant savings: 80% post battery electric retrofit

Maintenance savings: 30% annual reduction post battery electric retrofit

Other benefits and upgrades: Reduced operating noise levels, video surveillance and recording, Automatic train protection system,

Remote Monitoring and Diagnostics: Provides real-time data, fault diagnostics, and self-diagnostics to streamline maintenance and prevent downtime.

Medha’s Battery Electric Conversions: Setting a new standard in sustainable rail innovation

More Zero Emission Locomotive Case studies.

Model: Watco

Type: Diesel Electric to Battery Electric Conversion

Speed: 35 km/h

Power: 2000 hp battery equivalent

Build: Zero emission conversion

Nos: 2

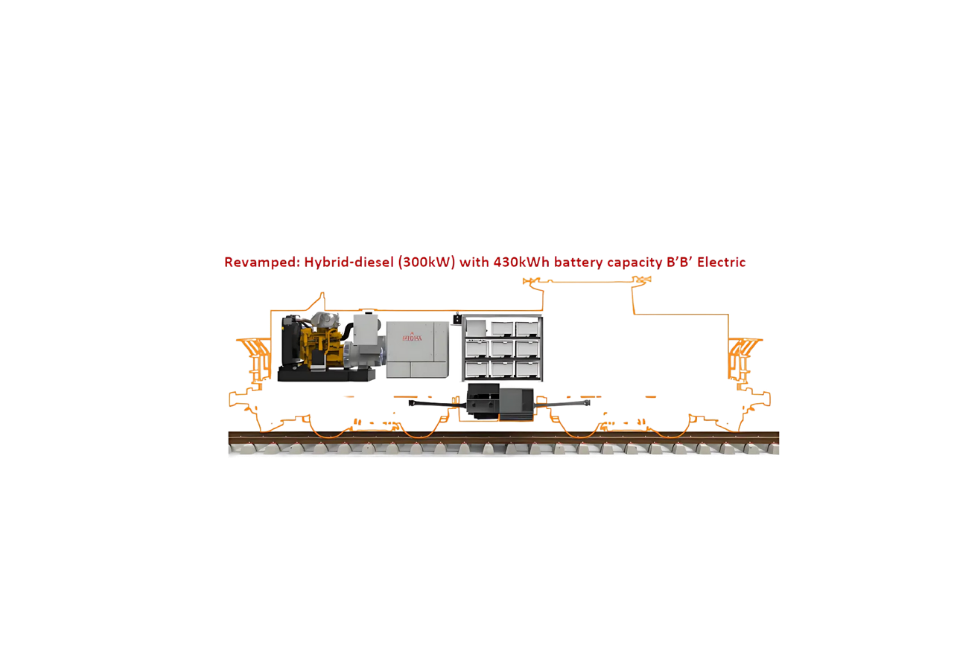

Model: G6 Vossloh (3 Axle)

Type: Diesel Hydraulic to Battery Electric Conversion

Speed: 100 km/h

Power: 670 kW

Build: Zero emission conversion

Nos: 1

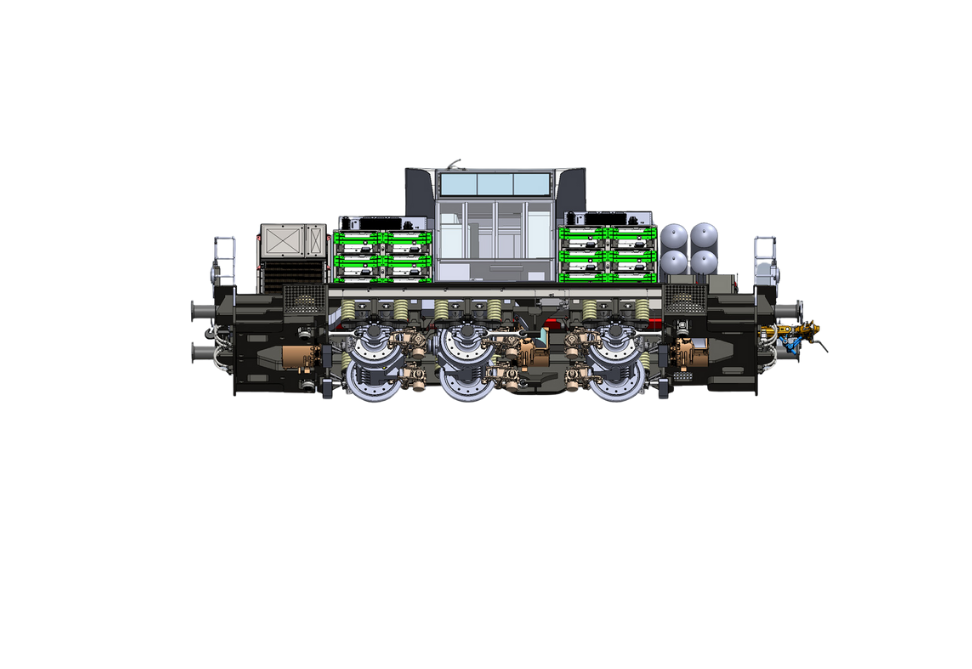

Model: Restoration (4 Axle)

Type: Diesel Hydraulic to Battery Hybrid Conversion

Speed: 100 km/h

Power: 730 kW

Build: Hybrid conversion

Nos: 1