Haul Trucks

Medha focuses exclusively on zero-emission vehicles in the mining sector. We perform the powertrain and battery sizing design analysis to meet operational needs, as well as design, manufacture and collaborate and build systems to integrate the zero emission kits in to OEM vehicle body.

Haul trucks that operate in a surface mine to carry ore, coal, overburden can be broadly classified as per below from a Battery Electric perspective.

(i) 90 t to approx. 136 t having Diesel mechanical propulsion

(ii) 136 t to 275 t having Diesel electric propulsion, and

(iii) Ultra haul trucks: 275 t and above having Diesel electric propulsion

Medha’s electric powertrain and energy storage system kit caters to the full spectrum of sizes, variance and capacity of the above mining vehicles.

Medha undertakes Battery Electric conversions of existing mining vehicles as well. We customize the zero-emission conversion to bespoke needs of the customer. Customers can be rest assured of the success and satisfaction of the conversion as we are both the manufacturer of the electric powertrain and the integrator as well.

Integrated Electric Powertrain: Medha offers a complete powertrain solution, including the battery pack and management systems for heavy haul vehicles

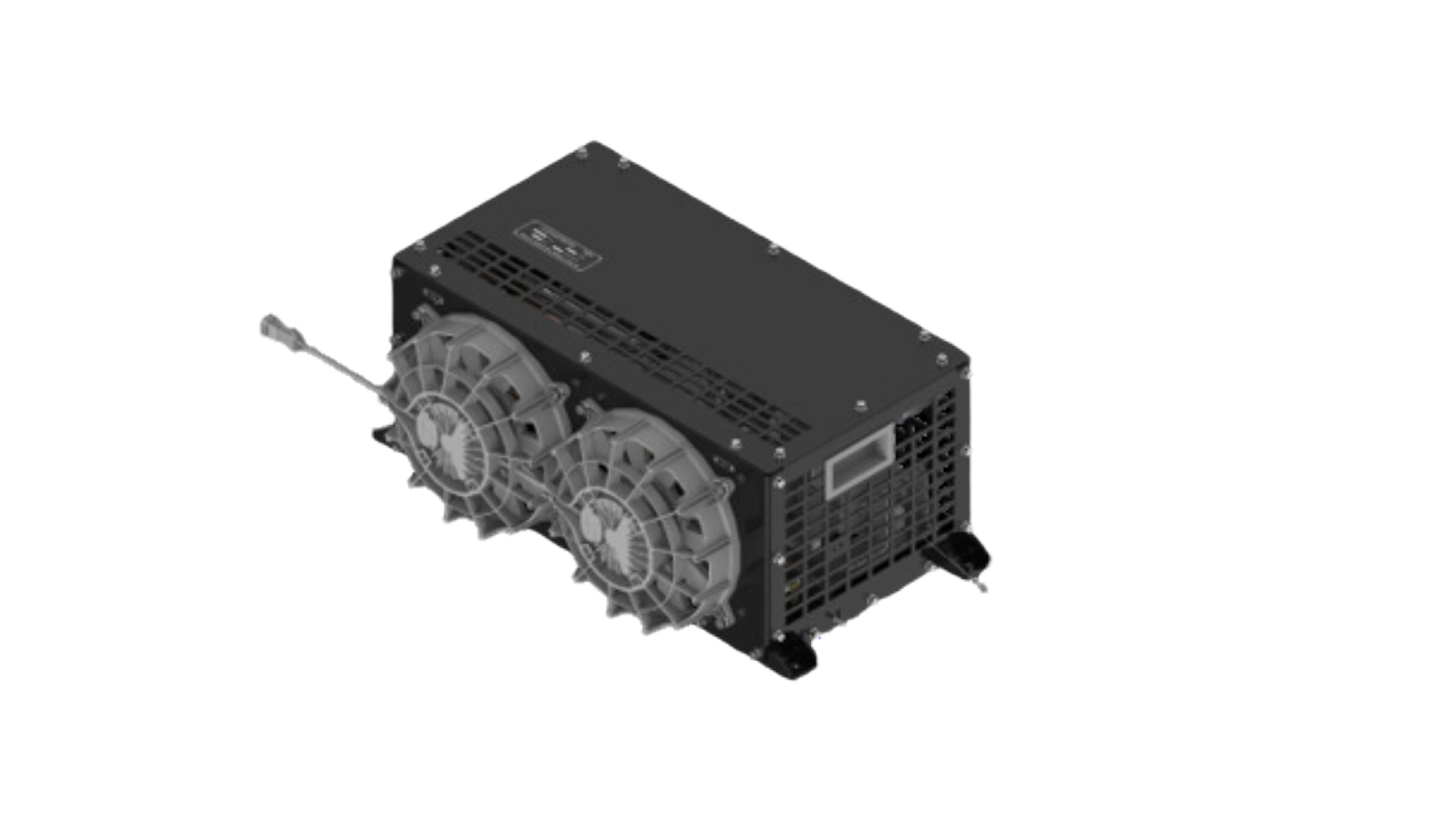

Permanent Magnet Synchronous Motor (PMSM): The motor provides high torque with peak efficiency, which is critical for optimized energy use and performance. The motors offered are standalone motors with gearboxes or integrated torque-power motor with gearboxes to suit different application

Regenerative Braking: Captures braking energy to extend range and improve overall energy efficiency

Advanced Converter Control: Integrated Converter technology maximizes efficiency and supports smooth power delivery for diverse operating conditions

Rugged and Low-Maintenance: Built for durability, the powertrain is engineered to endure the rigorous demands of commercial applications, reducing maintenance needs

High-Precision Vehicle Control Unit (VCU): Ensures accurate propulsion control with configurable vehicle and battery parameters

Sensorless Control Technology: Facilitates efficient motor operation and enhances reliability by reducing sensor dependency

Liquid-Cooled Motor and Components: Ensures stable operation across a range of temperatures with effective cooling solutions

Modular Design for Flexibility: Allows for integration in both new electric buses and retrofit applications for existing fleets

Comprehensive Diagnostics and IoT Capability: Provides real-time monitoring and diagnostics for optimized maintenance through CAN with OBD and IoT integration

Case study gallery.

Model: HM 70 t

Build and year: Battery Electric Conversion 2023

Medha has refurbished the mechanicals, designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck. Vehicle integration and mining trials are successfully completed.

Model: Volvo-Eicher 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck. Vehicle integration and mining trials are successfully completed.

Model: Mahindra 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck.

Model: Mahindra

Build and year: Battery Electric Conversion, 2023

Medha has performed the mechanical refurbishment and designed, supplied, and integrated electric powertrain and energy storage kit for the truck. Vehicle is operating successfully.