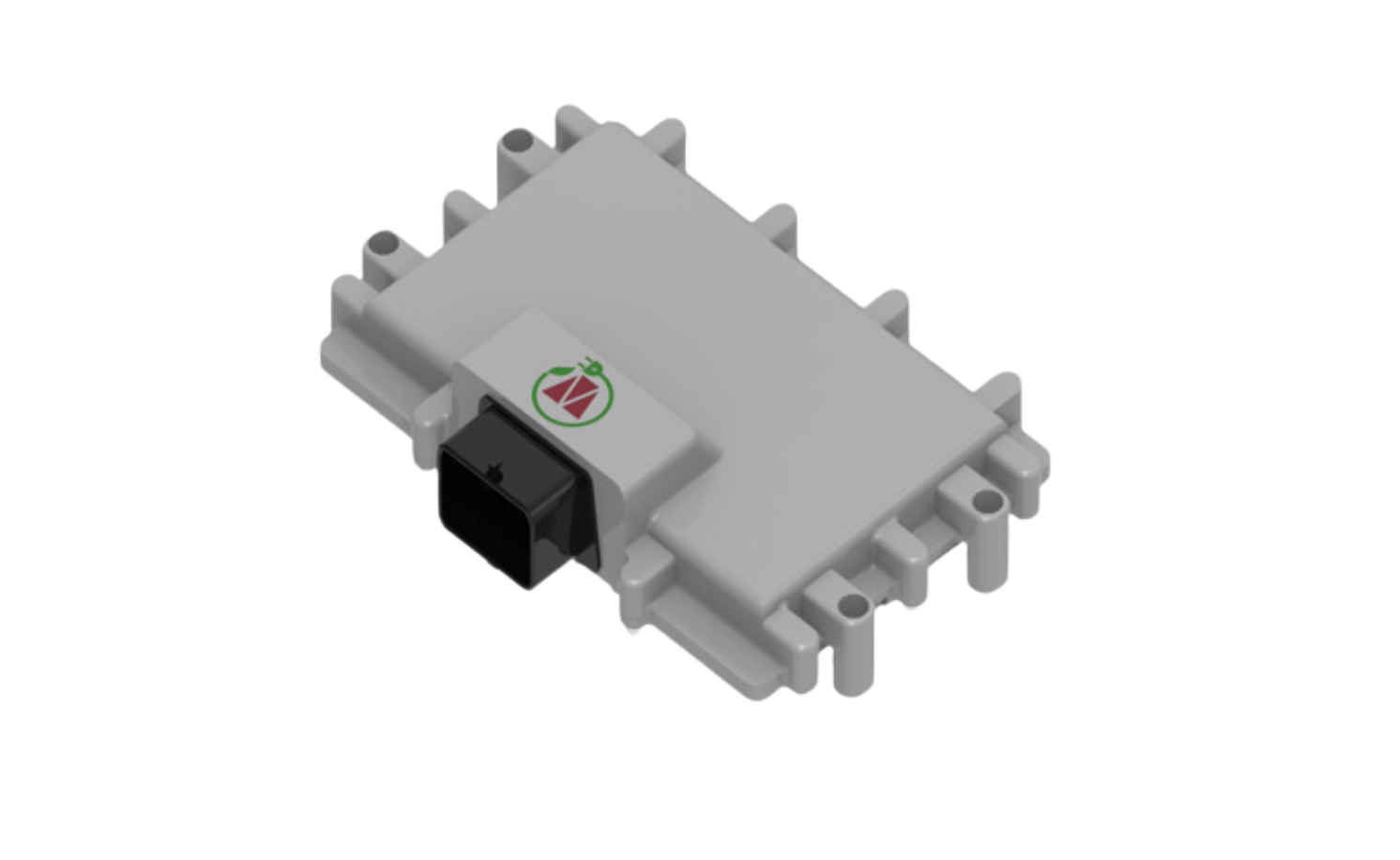

Medha’s Battery Management System (BMS) is a sophisticated electronic system designed to optimize the performance, safety, and longevity of battery packs in electric buses and trucks. It plays a crucial role in monitoring and controlling various parameters of the battery pack, including cell voltage, temperature, and state of charge (SOC).

Safety Protection Features

Medha’s BMS is equipped with multiple layers of protection to safeguard the battery cells and prevent potential hazards. Key safety features include

- Cell Over Voltage Protection and Cell Under Voltage Protection to maintain optimal cell voltage levels.

- Over Current in Charge & Discharge Protection and Short Circuit in Charge & Discharge Protection to prevent excessive current flow and short circuits.

- Over-temperature and under-temperature protection in charge and discharge protection ensure the battery operates within safe temperature ranges.

- Charge Protection and Discharge Protection to prevent damage from overcharging or deep discharging.

- Pack Over Voltage Protection and Pack Under Voltage Protection to protect the entire battery pack.

- SoC Fast Change Protection to manage rapid changes in the state of charge.

- Control Power Supply Error Protection to handle power supply issues.

- Packs Inner Communication Fault and Communication Branch Break Fault to detect and manage communication errors.

- BTMS System Fault, Current Sensor Fault, and Charge and Discharge Contactors Fault to identify and address specific system faults.

These features collectively ensure the BMS can protect the battery cells from various potential hazards, enhancing the overall safety and reliability of the electric vehicle.

Operational Features

Medha’s BMS also has a range of operational features designed to optimize performance and integration:

- 8 V to 36 V Working Voltage Range: This wide voltage range allows the BMS to operate with different battery configurations.

- 4x CAN Lines and 2x ISO SPI Channels: These communication interfaces enable seamless integration with other vehicle systems.

- 8x Digital Input Channels and 6x Active High Digital Output Channels: These channels provide flexible input and output options for various control and monitoring functions.

- 4x Active Low Digital Output Channels, 4x Analog Input Channels, and 4x Analog Output Channels: These additional channels support a wide range of sensor and actuator connections.

- Flash, SRAM & FRAM Interface: These memory interfaces ensure reliable data storage and retrieval.

- RS232 Interface: This standard communication interface facilitates easy diagnostics and configuration.

- ISO 7637 Test Pulse Capability: The BMS is capable of withstanding ISO 7637 test pulses, ensuring its resilience against electrical disturbances.

Together, these operational features make Medha’s BMS a versatile and powerful tool for managing electric vehicle batteries, ensuring both safety and performance.