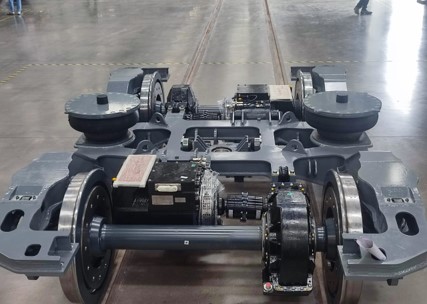

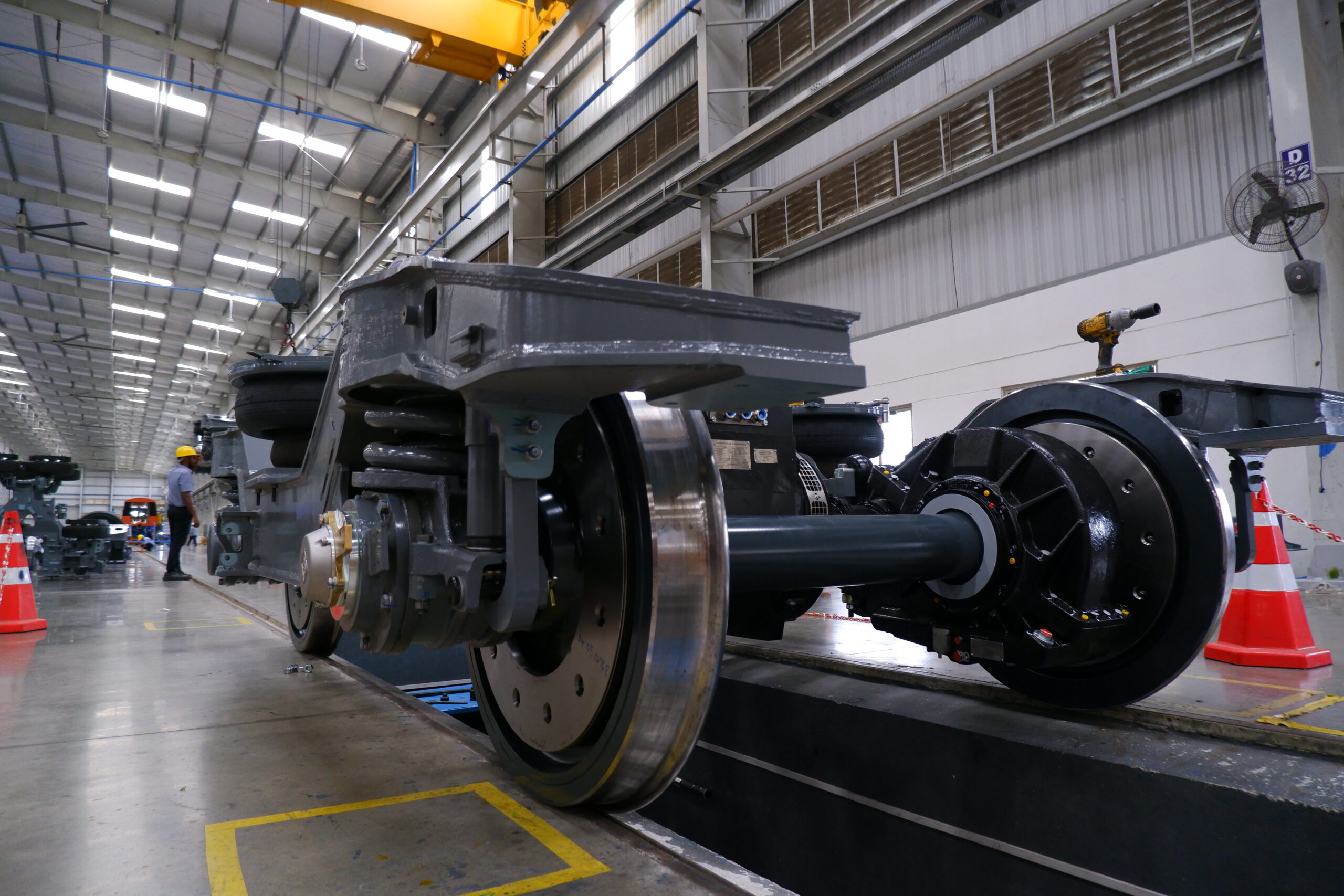

Bogies are essential components of railway vehicles, providing support for the car body and carrying the wheels. Medha designs and manufactures high-quality bogies for various railway mainstream applications as well as Special purposes.

Production Capacity

- 1500 bogies per year with scope to further increase capacity

- Production area: 450×75 m (each bay of 24 m)

- In-house facilities: sheet metal cutting, bending, edge milling, welding, stress relieving, painting and final assembly

- EN15085 certified welding compliance

- Robotic welding machines

Key Components and Features of Medha Bogies

- Bogie Frame: The primary structural component of the bogie, supporting the wheels, axles, and other components.

- Axles: The rotating shafts that connect the wheels to the bogie frame.

- Wheels: The circular components that provide traction and support for the vehicle.

- Suspension System: A system that absorbs shocks and vibrations, ensuring a smooth ride for passengers.

- Brakes: The braking system, which is typically integrated with the wheels or axles.

- Gearbox

- Motor

- Other Components: such as springs, dampers, bearings, and electrical systems.

Manufacturing Process

The manufacturing process for Medha bogies involves several key steps:

- Design and Engineering: The design of the bogie is based on specific requirements, such as application, load capacity, speed, and track conditions.

- Material Selection: High-quality materials, such as steel, are selected for the bogie components.

- Fabrication: The components are fabricated using advanced manufacturing techniques, such as welding, machining, and assembly.

- Testing and Quality Control: Rigorous testing and quality control procedures are implemented to ensure that the bogies meet the required standards.

- Painting and Finishing: The bogies are painted and finished to protect them from corrosion and enhance their appearance.

Types of Bogies Manufactured by Medha

- Passenger train Bogies: These bogies typically have a lower load capacity and prioritize comfort and ride quality.

- Freight car Bogies: These bogies have a higher load capacity and are built to withstand heavy loads.

- Locomotive Bogies: These bogies withstand the weight of the locomotive and provide the necessary traction.

Benefits of Medha Bogies

- High Quality: Medha bogies are manufactured using advanced technology and high-quality materials, ensuring reliability and durability.

- Customization: Medha can customize bogies to meet specific customer requirements, such as load capacity, speed, and track gauge.

- Efficiency: Medha bogies are designed to be efficient, reducing maintenance costs and improving overall performance.

- Safety: Medha prioritizes safety in the design and manufacturing of its bogies, ensuring compliance with industry standards and regulations.

With our expertise in design, manufacturing, and quality control, Medha is committed to providing innovative and reliable bogie solutions that meet the needs of railway operators worldwide.