Medha has successfully delivered hydrogen fuel cell locomotives, setting a new benchmark in sustainable railway technology. These zero-emission locomotives provide a clean and efficient alternative to traditional diesel engines.

Medha also offers comprehensive conversion kits and turnkey solutions to install in new or transform existing diesel locomotives into fuel cell hydrogen units, achieving zero-emission compliance. This conversion is applicable to both 4-axle and 6-axle locomotives, ensuring they retain comparable horsepower and load-hauling capabilities to their diesel counterparts.

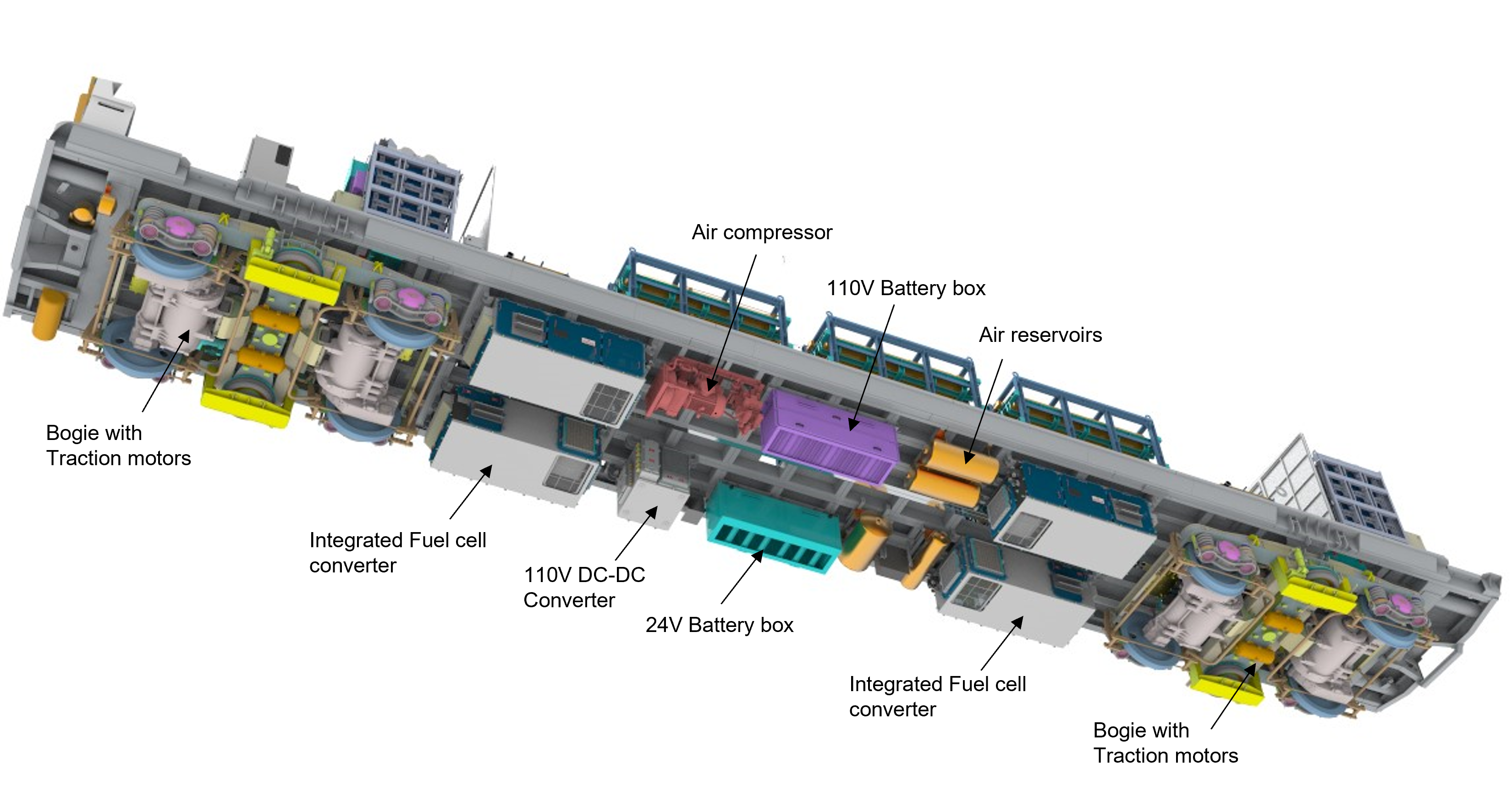

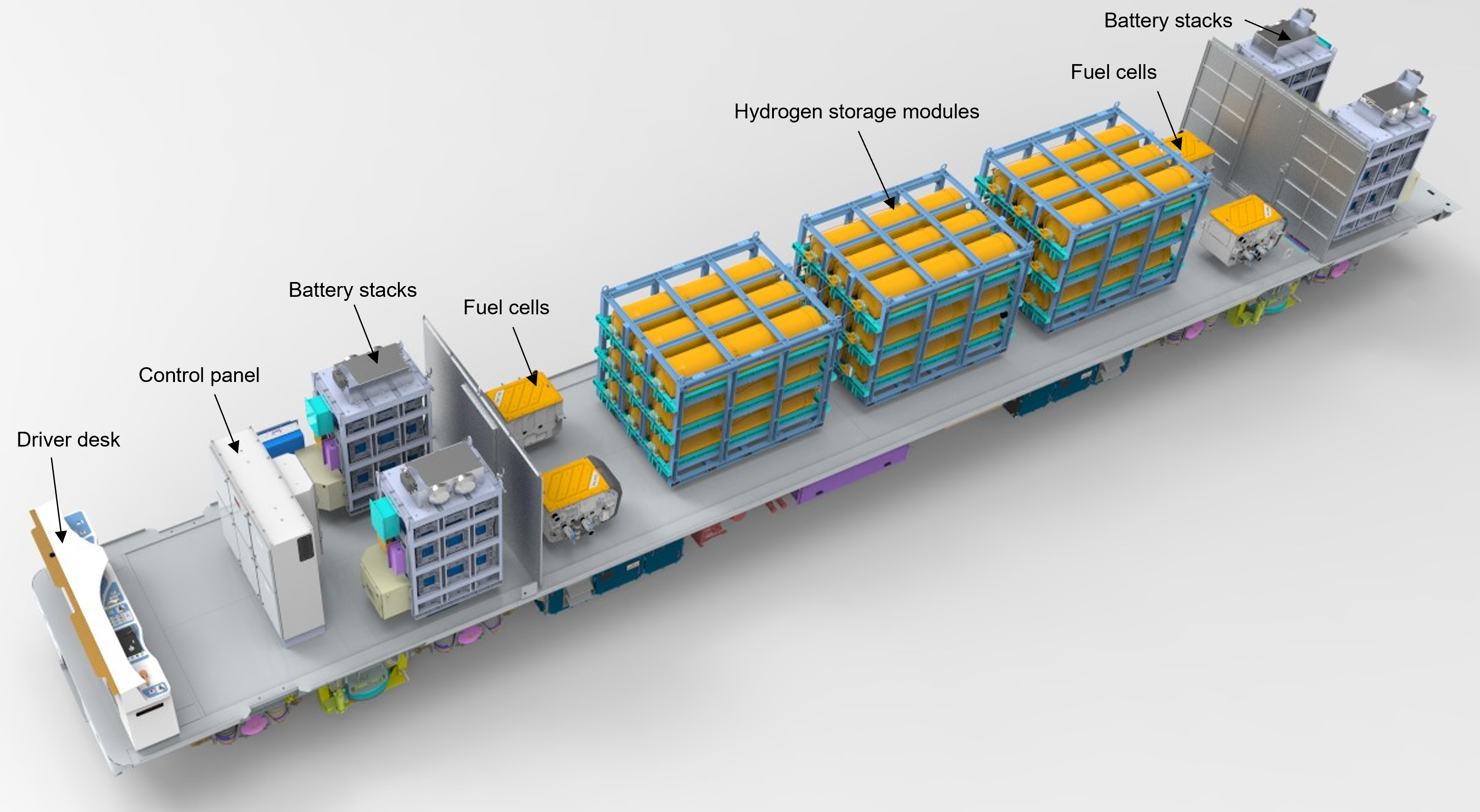

Hydrogen Electric Kit Conversion Components

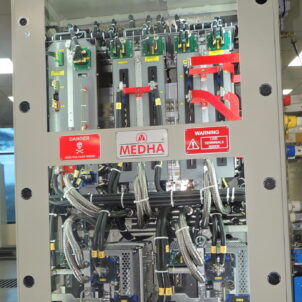

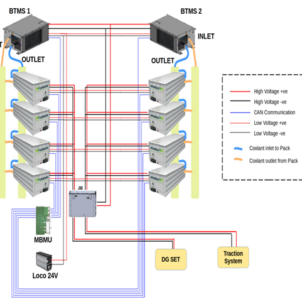

- ZE Locker: Pre-assembled and pre-tested, ready-to install unit. Includes power modules, locomotive control system, battery management system, contactors and electrical switchgear

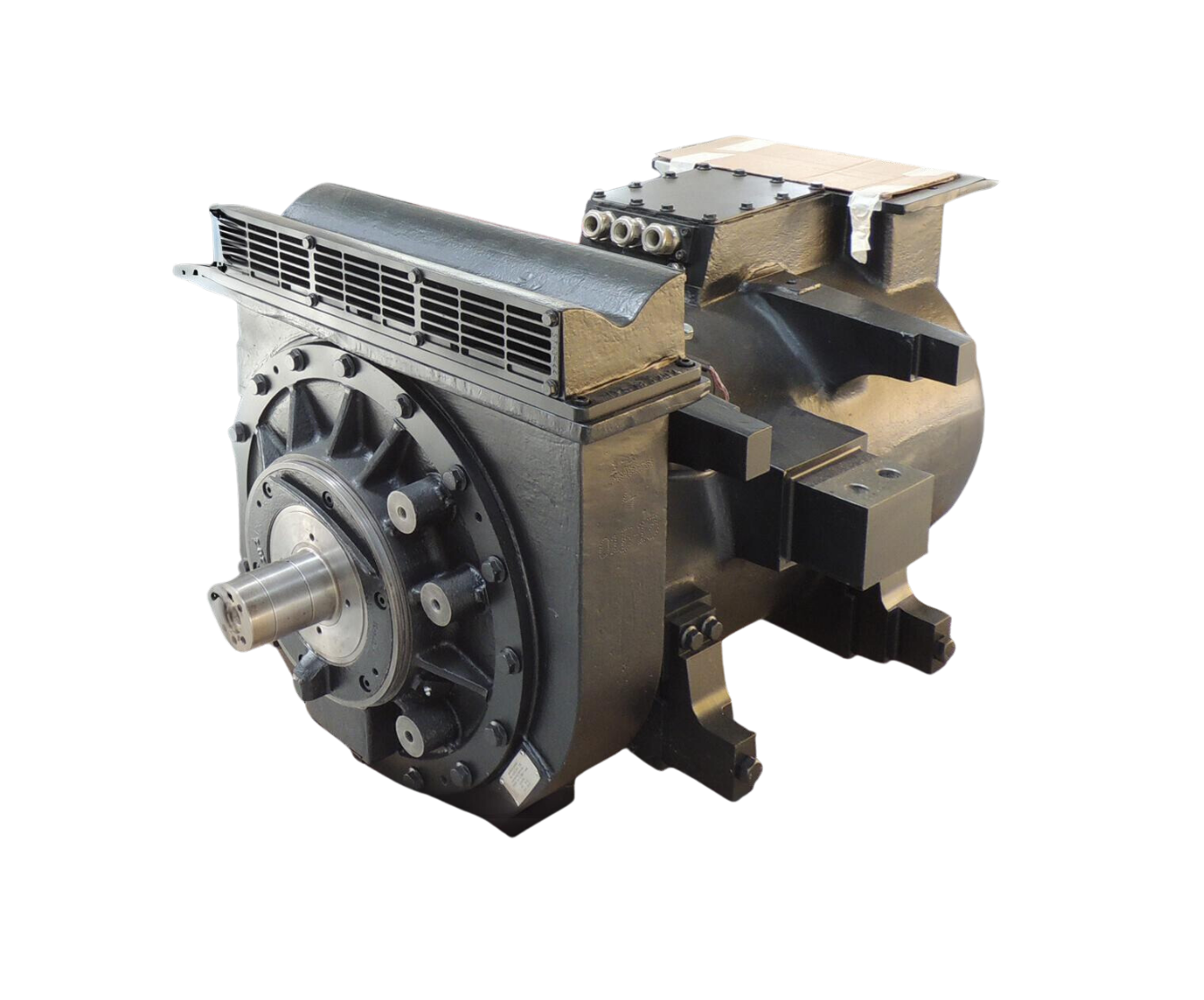

- AC Traction Motors (if customer prefers replacing existing DC Motors)

- ZEBHRA Converter

- Hydrogen Fuel Cells, and Storage

- Hydrogen Fuel Cell Boost Converter

- Hydrogen Fuel Cell Radiator

- Traction Battery package with integrated Battery Management System and Battery Thermal Management System

- Driver console

- Blower and compressors

- Sensors

- Hydrogen Refill Station and Battery Chargers of various types and ratings

Applications

- Industrial locomotives

- Shunters

- Intermodal, and

- Heavy haul.

Key Features

- Locomotive Remote Monitoring and Fault Diagnostics: Enables continuous oversight and quick identification of issues, enhancing operational reliability.

- Fuel Cell and Battery Health Monitoring and Energy Management: Provides real-time insights into battery status , thermal management and optimizes energy usage for extended operational range.

- Electrically Driven Traction Motor Blowers and Compressor: Improves energy efficiency and reduces mechanical complexity.

- Emergency Power Cut-Out: Ensures safety by allowing immediate power shutdown in critical situations.

- Improved Driver Comfort Features: Enhances the working environment for operators, contributing to better performance and satisfaction.

- Similar or better performance as original Diesel Locomotives: Facilitates a seamless transition for operators accustomed to diesel engines.

- Reduced Number of Moving Parts: Decreases maintenance requirements and enhances reliability.

- Auto-Test Modes: Simplifies diagnostics and maintenance procedures.