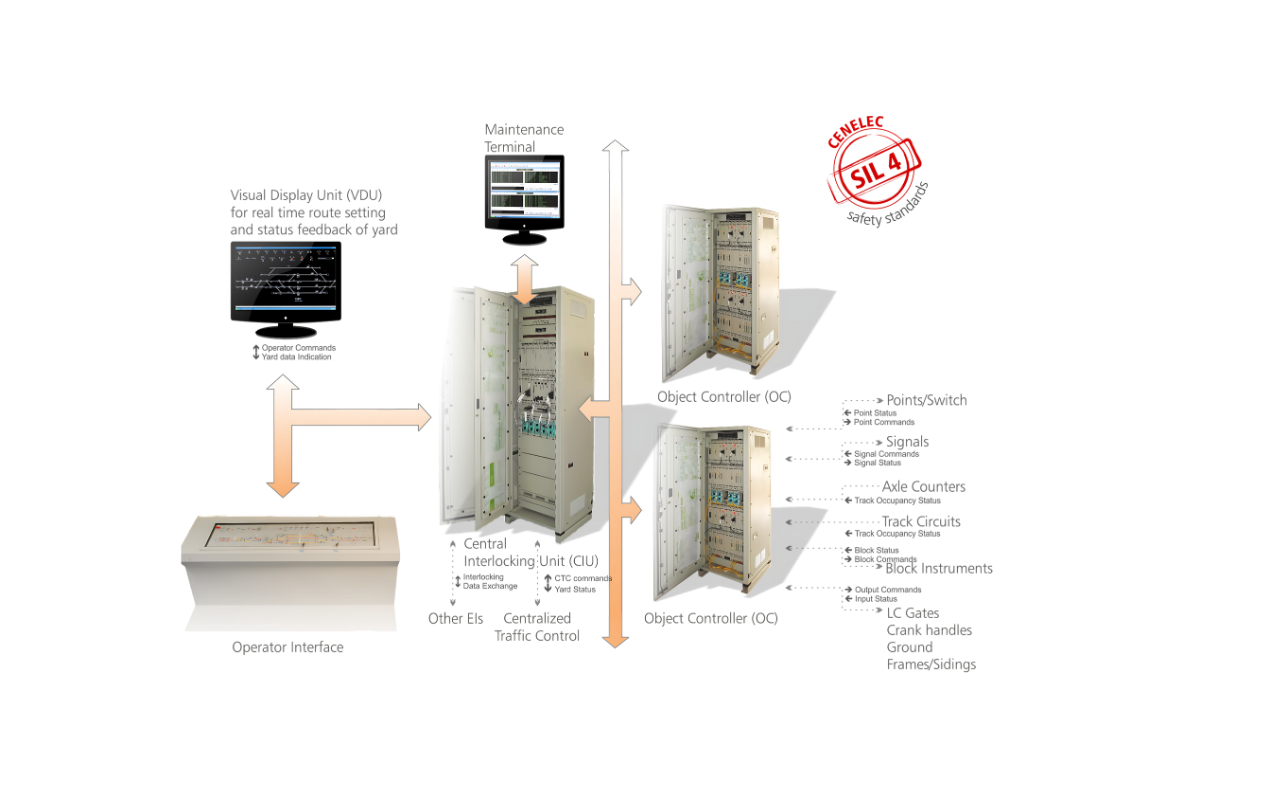

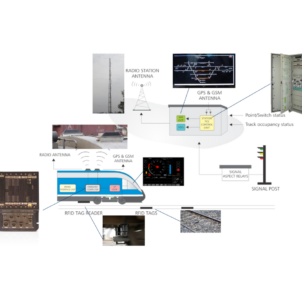

Medha’s Electronic Interlocking System MEI 634 is a cutting-edge, fail-safe Distributed Interlocking System designed to meet the highest safety standards (SIL-4) in compliance with CENELEC requirements. The system features a two-out-of-two architecture with hot standby and automatic change-over, ensuring reliable and seamless operations.

MEI 634 provides a comprehensive suite of interlocking functions, such as Route Setting, Route Release, Point Operation, Track Occupancy Monitoring, Overlap Protection, Crank Handle Operation, Level Crossing Gate Interlocking, and provision for Block Working. The MEI 634 is a versatile, modular interlocking system capable of managing between 64 and 2,200 vital inputs/outputs. It can be deployed as wayside equipment in the yard or installed in the Station Equipment Room for larger applications.

Key System Components

Central Interlocking Unit (CIU)

- Utilizes a two-out-of-two architecture with dual independent channels processing vital interlocking logic.

- Features a supervisory processor to monitor both vital computing channels.

- Offers hot standby with automatic change-over, ensuring uninterrupted functionality.

- Includes redundant communication channels to the Object Controller (OC) and Panel Processor (PP), with an OFC ring configuration for robust connectivity.

Object Controllers (OC)

- Controls field equipment using fail-safe signalling relays.

- Supports up to 48 OCs. Each OC can manage 64 bits of Vital Inputs and 32 bits of Vital Outputs, enabling a maximum capacity of 1,344 Vital Inputs and 864 Vital Outputs.

- Equipped with dual communication modules for redundancy.

- Features 8 Wayside Function Modules (WFMs) per OC, each capable of managing 8 vital inputs or outputs using two-out-of-two architecture for high reliability.

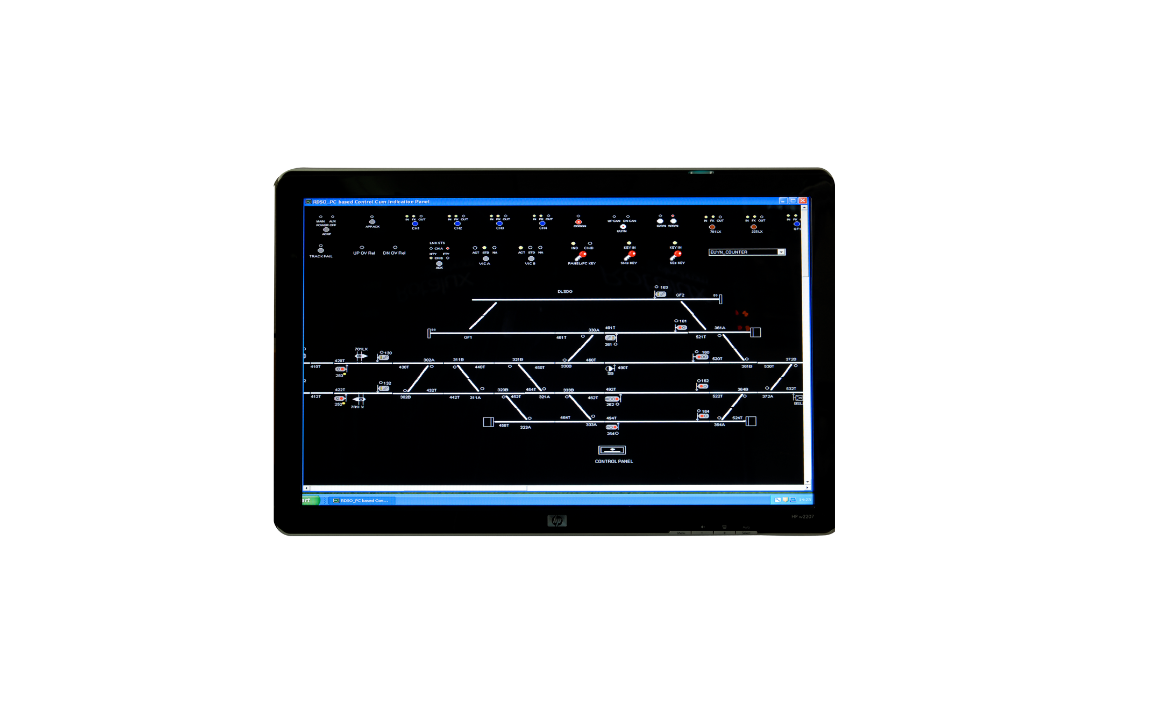

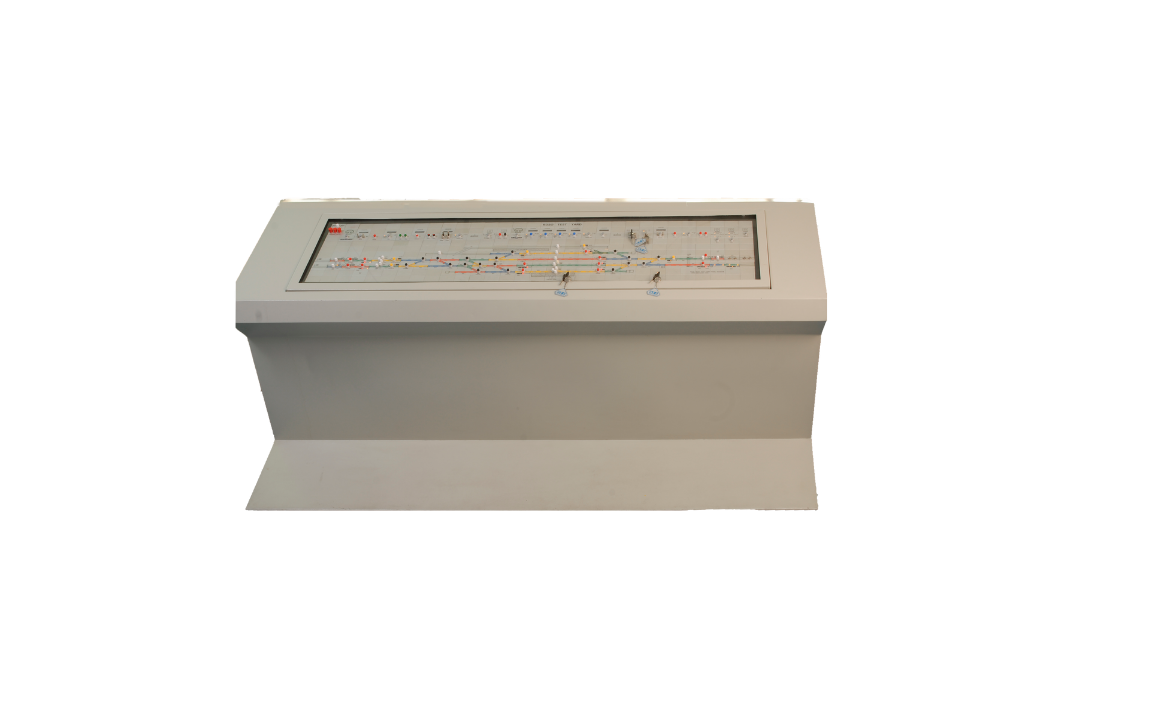

Panel Processor (PP)

- Interfaces between the Operator’s Panel and the CIU, providing a seamless user experience.

- Includes a Windows-based, user-friendly Application Data Generation tool suite with extensive automation for creating yard-specific application data.

- Supports reverse compilation and relay diagram generation for simplified verification of application data.

Maintenance Terminal

- Provides a comprehensive diagnostic interface with real-time event, fault, and yard status displays.

- Features online and offline event logging with date and time stamps for detailed analysis.

- Enables efficient maintenance through complete fault records and event logs.

Why Choose Medha’s MEI 634?

- Fail-Safe Design: Built on a SIL-4 compliant two-out-of-two architecture with hot standby for maximum safety and reliability.

- Comprehensive Interlocking Features: Supports a wide range of interlocking functions for enhanced safety and operational efficiency.

- Redundant and Robust Communication: Ensures continuous and reliable connectivity through dual channels and OFC ring configuration.

- User-Friendly Tools: Includes advanced software tools for easy data generation, verification, and maintenance.

- Extensive Diagnostics: Offers powerful diagnostic capabilities with real-time and historical data for effective troubleshooting.

Medha’s MEI 634 is a state-of-the-art solution that delivers unmatched safety, efficiency, and ease of use, making it ideal for modern railway operations.