Medha has successfully converted an existing 70 t mining truck to battery-electric by performing essential mechanical modifications and integrating a turnkey battery-electric powertrain and energy storage system. Vehicle integration and mining trials have been successfully completed. Converting existing vehicles offers a swift pathway to decarbonization, extending asset lifespan, and minimizing waste by repurposing valuable equipment.

Integrated Electric Powertrain: Medha designed and manufacture the complete powertrain solution, including the battery pack, specifically designed for medium and heavy commercial vehicles

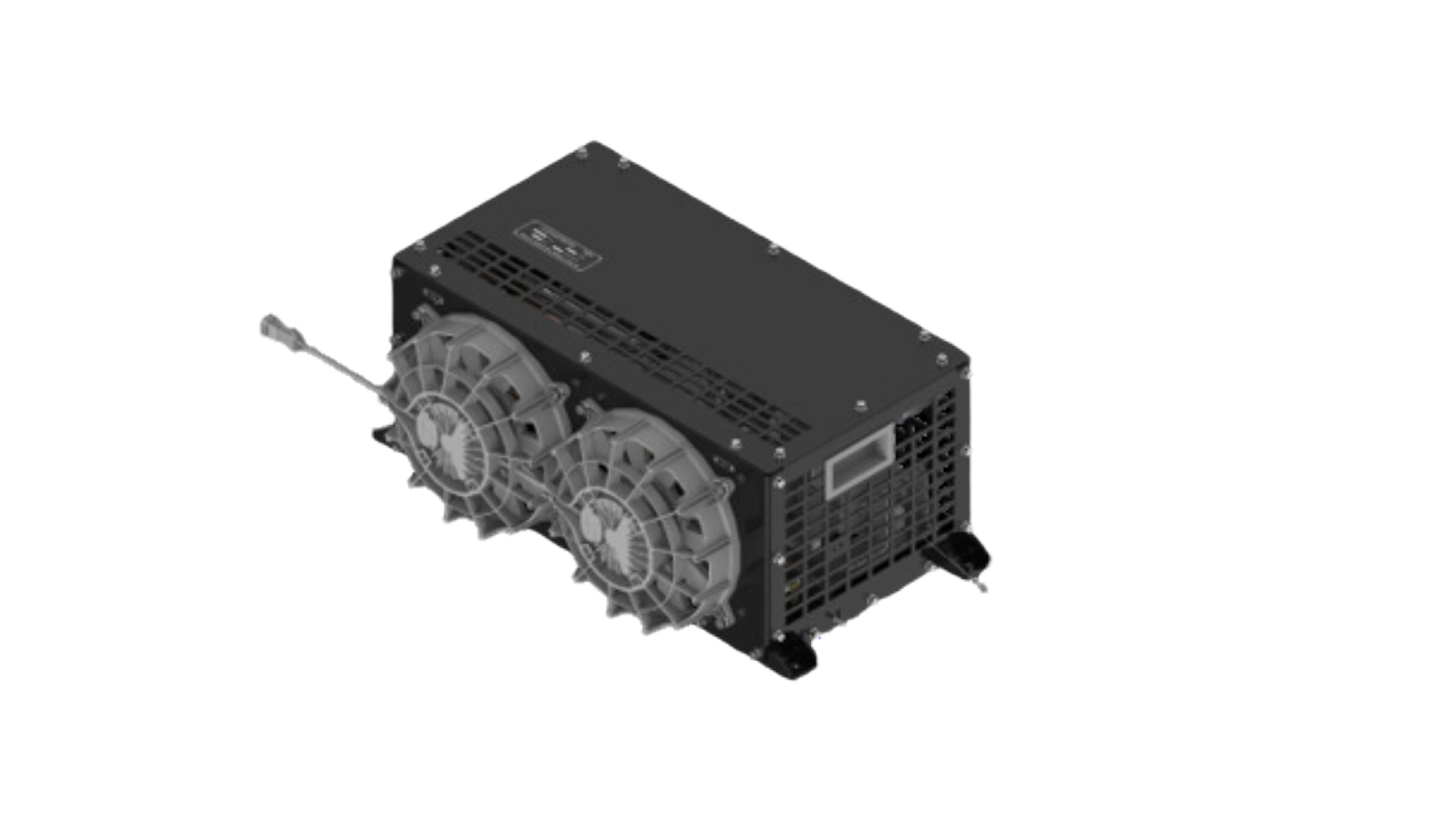

Permanent Magnet Synchronous Motor (PMSM) with integrated 6 speed gearbox: The motor provides high torque with peak efficiency, which is critical for optimized energy use and performance

Regenerative Braking: Captures braking energy to extend range and improve overall energy efficiency

Advanced Converter Control: Integrated Converter technology maximizes efficiency and supports smooth power delivery for diverse operating conditions

Rugged and Low-Maintenance: Built for durability, the powertrain is engineered to endure the rigorous demands of commercial applications, reducing maintenance needs

High-Precision Vehicle Control Unit (VCU): Ensures accurate propulsion control with configurable vehicle and battery parameters

Sensorless Control Technology: Facilitates efficient motor operation and enhances reliability by reducing sensor dependency

Liquid-Cooled Motor and Components: Ensures stable operation across a range of temperatures with effective cooling solutions

Modular Design for Flexibility: Allows for integration in both new electric trucks and retrofit applications for existing fleets

Comprehensive Diagnostics and IoT Capability: Provides real-time monitoring and diagnostics for optimized maintenance through CAN with OBD and IoT integration

Medha Zero-Emission Solutions: Driving the World Toward a Greener, Sustainable Future

Case study gallery.

Model: Volvo-Eicher 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck. Vehicle integration and mining trials are successfully completed.

Model: Mahindra 35 t

Build and year: OEM New, 2024

Medha has designed, supplied, and integrated our turnkey battery electric powertrain and energy storage kit for the truck.

Model: Ashok Leyland 3718T

Build and year: Battery Electric Conversion, 2023

Medha has performed the mechanical refurbishment and designed, supplied, and integrated electric powertrain and energy storage kit for the truck. Vehicle is operating successfully.